DIY Circular Saw Guide: 7 Easy Steps for Perfect Cuts

Disclosure: This post may contain affiliate links from online retailers, including Amazon. If you click a link and buy tools or supplies, I may earn a small commission—at no extra cost to you. This allows me to provide you free helpful content, and I genuinely appreciate your support🤝 Learn more

If you’ve ever tried to make a long, straight cut with a circular saw, you’ve probably experienced the frustration of wobbly lines, binding blades, and uneven edges. Even with a steady hand and a sharp blade, getting precision cuts can feel impossible—especially if you’re working with plywood, MDF, or long boards.

I get it. As a lifelong carpenter and DIYer, I’ve been there. Before I knew better, I’d try to follow a chalk line freehand, only to end up with cuts that were just slightly off—which, as you probably know, is enough to ruin an entire project. A fraction of an inch inaccuracy can mean doors don’t fit right, shelves wobble, and joints don’t align.

That’s why a DIY circular saw guide can be a game-changer. Instead of spending hundreds of dollars on a track saw, you can build your own custom DIY circular saw guide in about 30 minutes using scrap wood and a few simple tools. And the best part? It works just as well as expensive store-bought versions, allowing you to make perfectly straight, accurate cuts every single time.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Why You Need a DIY Circular Saw Guide

- Straight Cuts Without Hassle: Eliminates guesswork and keeps your saw locked on track.

- Safer Cutting: Reduces the risk of kickback and keeps your hands away from the blade.

- Saves Money: No need for an expensive track saw when a DIY circular saw guide does the job.

- Perfect for Beginners: Even if you’re new to DIY, this project is quick, easy, and foolproof.

This guide will walk you through everything you need to know about making your own DIY circular saw guide, step by step. Whether you’re a total beginner or an experienced builder looking for a better cutting system, you’ll find pro tips, mistakes to avoid, and advanced modifications to make your saw guide even more versatile.

By the end of this article, you’ll not only have a custom-made DIY circular saw guide for your projects, but you’ll also have the confidence to tackle larger and more complex woodworking projects with precision.

Let’s get started.

Understanding Circular Saw Guides

If you’ve ever struggled to make perfectly straight cuts with a circular saw, you’re not alone. Unlike table saws or track saws, circular saws are designed for portability—not precision. The good news is that with a DIY circular saw guide, you can turn your saw into an accurate cutting machine without spending a fortune.

But before we jump into building one, it’s important to understand what a circular saw guide is, how it works, and the different types available.

What is a Circular Saw Guide?

A circular saw guide is a straight edge or track system that helps you guide your saw in a perfectly straight line when making cuts. Instead of relying on a freehand cut or following a drawn line, the saw glides along the guide, ensuring precision and repeatability on every pass.

Whether you’re breaking down full plywood sheets, trimming long boards, or making rip cuts, a DIY circular saw guide eliminates errors and helps you cut faster, safer, and more efficiently.

How a DIY Circular Saw Guide Works

A DIY circular saw guide typically consists of two main parts:

- A base piece – This is a flat, stable board (usually plywood or MDF) that serves as the guide’s foundation.

- A straightedge or fence – A perfectly straight piece of wood or metal that the saw runs along, keeping your cut on track.

When the circular saw is placed against the fence and moved forward, it cuts exactly along the edge of the guide, resulting in a perfectly straight line—every time.

Types of Circular Saw Guides

Not all circular saw guides are the same. Depending on your project, you might need a different type of guide to get the best results. Here are the most common types:

1. Straight Edge Guide (Most Common DIY Option)

- The simplest type of DIY circular saw guide.

- Uses a long, straight piece of plywood, MDF, or aluminum as a guide.

- Perfect for long rip cuts and crosscuts on plywood and lumber.

2. Rip Cut Guide

- A compact, adjustable guide that helps cut parallel to the edge of a board.

- Best for making repetitive rip cuts at consistent widths.

- Examples: Kreg Rip-Cut, simple edge guide for circular saw.

3. Crosscut Guide

- Designed for cutting across the grain with precision.

- Often includes a built-in measuring stop for consistent repeat cuts.

- Great for cutting shelf pieces, cabinet parts, or framing components.

4. Track Saw System

- A high-end version of a circular saw guide with an aluminum track.

- Guides the saw along a pre-set rail for smooth, laser-straight cuts.

- Examples: Kreg Accu-Cut, Makita Guide Rail, Festool Track Saw System.

Why a DIY Circular Saw Guide Might Be the Best Choice

While store-bought guides like the Kreg Accu-Cut or Festool track systems work very well, they can be expensive. A DIY circular saw guide offers:

✔️ Custom Sizing – Build a guide to fit your exact saw and project needs.

✔️ Budget-Friendly – Use scrap wood or inexpensive materials.

✔️ Just as Accurate – With proper setup, a DIY guide works as well as high-end models.

✔️ Easy to Make – You can build one in less than 30 minutes with basic tools.

Key Takeaways

- A circular saw guide helps ensure straight, precise cuts without needing a track saw.

- There are different types of guides depending on your cutting needs.

- A DIY circular saw guide is cost-effective, customizable, and just as accurate as expensive store-bought options.

In the next section, we’ll go step-by-step through everything you need to build your own DIY circular saw guide.

Materials and Tools Needed

Before diving into the step-by-step build, let’s go over everything you need to make a DIY circular saw guide. The best part? You likely already have most of these materials in your workshop.

Choosing the Right Materials

The materials you use will determine how accurate, durable, and reliable your guide is. While you can make a DIY circular saw guide out of almost anything, using warped, uneven, or low-quality materials will result in crooked cuts and poor performance.

Here’s what I recommend for the best results:

Base Material (Guide Surface)

✔ 1/4″, 1/2″, or 3/4″ Plywood (Preferred) – The thicker the plywood you use the shallower your max cutting depth will be.

✔ MDF (Medium-Density Fiberboard) – Very smooth and straight but can break down over time.

✔ Hardboard (Masonite) – Ultra-thin and smooth but best for short-term use.

➡ Tip: Avoid warped, bowed, or flimsy materials. If your base isn’t straight, your cuts won’t be either.

Straightedge (Fence)

✔ Factory-Edge Plywood Strip – A pre-cut factory edge ensures straightness.

✔ Aluminum Straightedge – Extremely durable and won’t warp over time but you’ll have to go buy one.

✔ Hardwood Strip (Maple, Oak, or Poplar) – More rigid than plywood but requires precision cutting.

➡ Tip: Your straightedge is the most important part of your DIY circular saw guide—it’s what ensures every cut is dead straight.

Essential Tools for Building a DIY Circular Saw Guide

You won’t need any fancy tools—just basic woodworking essentials that most DIYers already own.

✔ Circular Saw – The reason we’re making this guide! Works with any standard model.

✔ Tape Measure – For precise layout and marking.

✔ Framing Square or Speed Square – Ensures perfect 90-degree alignment.

✔ Clamps (C-Clamps or Quick-Grip Clamps) – Holds everything steady while cutting.

✔ Drill + Wood Screws – Reinforce the straightedge. Can also be glued

✔ Fine-Grit Sandpaper (120–220 Grit) – Smooths out edges for a friction-free glide.

➡ Optional but Helpful:

✔ Track Saw Rail (if upgrading later) – Allows you to convert your guide into a more advanced track system.

✔ Router with Flush Trim Bit – Ensures a perfectly flush edge if cutting the guide by hand.

✔ Double-Sided Tape (Instead of Clamps) – Holds pieces temporarily without slipping.

Key Considerations When Choosing Materials & Tools

🔹 How Often Will You Use It? – If you’re making a long-term guide, use high-quality plywood or aluminum. If it’s just for a single project, MDF or hardboard will work fine.

🔹 What’s Your Circular Saw Size? – Make sure the base is wide enough to accommodate your specific saw.

🔹 Do You Need Portability? – If you need to store or transport it, consider a foldable or modular design.

🔹 Plywood Thickness – The thicker the plywood you use for the guide base, the less cutting depth you’ll have for your saw.

Key Takeaways

✔ Using high-quality, straight materials is the key to an accurate DIY circular saw guide.

✔ A factory-edge straightedge ensures laser-straight cuts and prevents errors.

✔ Basic tools like a circular saw, clamps, and a square are all you need to build this guide.

Now that you’ve got everything ready, let’s move on to building your DIY circular saw guide step by step.

Step-by-Step Guide to Building a DIY Circular Saw Guide

Now that you have your materials and tools ready, it’s time to build your own DIY circular saw guide. This process is quick, straightforward, and beginner-friendly—you’ll be making perfectly straight cuts in no time.

Follow these step-by-step instructions carefully to ensure your guide is accurate and durable.

Step 1: Cut the Base to Size

🔹 Goal: Create a flat, stable base that will support your straightedge and saw.

✅ Measure and mark your base material (plywood, MDF, or hardboard) to be 8 to 12 inches wide and a few inches longer than your longest cut length (typically 4 or 8 feet for sheet goods).

✅ Clamp down the material securely on a workbench or sawhorses.

✅ Use your circular saw to cut the base to size, making sure the edge stays as straight as possible.

➡ Pro Tip: If you don’t trust your freehand cut, use a straightedge or factory-cut edge as a guide for this first cut.

Step 2: Attach the Straightedge (Fence)

🔹 Goal: Secure a perfectly straight guide for your saw to follow.

✅ Choose a factory-edge plywood strip (cut to 3-4″, aluminum straightedge, or hardwood board that is perfectly straight (this will be your fence).

✅ Position it about 4 to 5 inches from one side of your base—this will leave room for your circular saw to run along the track.

✅ Use wood glue and clamps to hold the straightedge in place. (If using a wood fence)

✅ For extra durability (required for aluminum fence), drill pilot holes and secure the fence with short screws (avoid long screws that could poke through the bottom of the base).

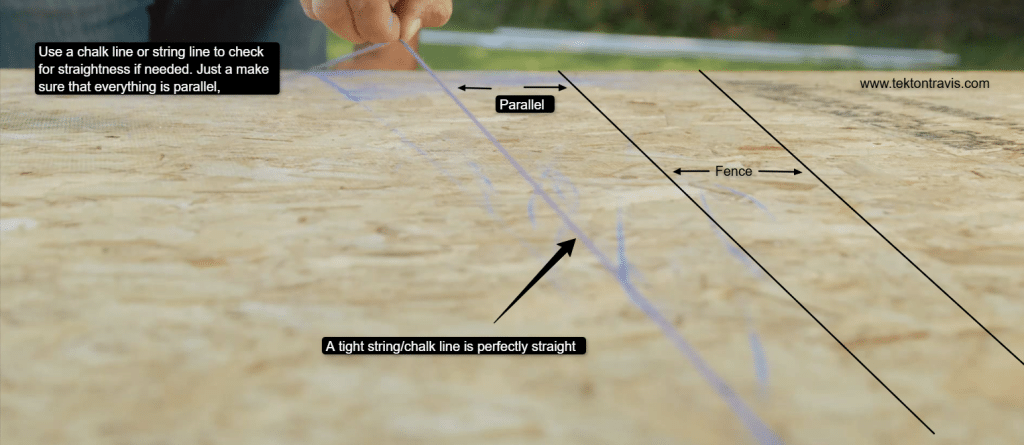

➡ Pro Tip: Double-check alignment before securing! If your straightedge isn’t 100% straight, your cuts won’t be either. If you don’t have a straight edge you can snap a chalk line where you will mount the fence or check straightness with a string line.

Step 3: Make the Zero-Clearance Cut

🔹 Goal: Trim off excess material so the guide aligns exactly with your saw blade.

✅ Position your circular saw against the straightedge as if making a cut.

✅ Turn on the saw and carefully cut along the guide, removing the excess material from the base.

✅ The new edge of the base now represents the exact cutting line—whenever you place this guide on your workpiece, the saw blade will cut exactly along the edge.

➡ Pro Tip: Always use the same saw with your guide. If you switch to a different saw with a different baseplate width, the cut alignment may be off.

Step 4: Test and Fine-Tune the Guide

🔹 Goal: Verify accuracy before using your DIY circular saw guide on an actual project.

✅ Place the guide on a scrap board or plywood sheet.

✅ Clamp it down securely and run your saw along the guide to make a test cut.

✅ Measure the cut’s straightness using a square or straightedge—it should be perfectly straight without deviation.

➡ Pro Tip: If the guide shifts while cutting, use stronger clamps or anti-slip tape underneath for extra grip.

Optional Modifications & Enhancements

If you want to take your DIY circular saw guide to the next level, here are some advanced modifications you can add:

✔ Extendable Design – Attach hinges or rail extensions to allow for longer cuts.

✔ Adjustable Stop Blocks – Add built-in stops to make repeat cuts faster and easier.

✔ Ruler or Measuring Tape Integration – Attach a measuring scale to the base for quick reference.

✔ Non-Slip Padding Underneath – Stick rubber or sandpaper strips to prevent shifting.

✔ Dust Collection Attachment – Modify your saw or guide for better dust control when cutting indoors.

Key Takeaways

✔ A properly built DIY circular saw guide eliminates crooked cuts and improves safety.

✔ The zero-clearance edge guarantees precision—your saw blade will always cut exactly where the guide is placed.

✔ Simple modifications can turn a basic guide into a highly efficient cutting system.

In the next section, we’ll cover tips for accurate and safe cuts using your new circular saw guide.

Pro Tips for Accurate, Safe, and Efficient Cutting

Now that your DIY circular saw guide is built, it’s time to use it effectively. Even with the best guide, small mistakes or poor cutting techniques can lead to inaccurate cuts, material waste, or even safety hazards.

To get the most out of your guide, follow these pro-level cutting techniques, avoid common mistakes, and consider advanced upgrades to take your cutting game to the next level.

✔ Essential Cutting Techniques for Precision

✅ Clamp the Guide Securely – Even a slight shift while cutting can throw off your accuracy. Use quick-grip clamps or C-clamps to keep the guide locked in place.

✅ Use the Right Blade for the Job – A fine-tooth blade (40-60 teeth) is best for clean plywood cuts, while a 24-tooth blade is ideal for fast rip cuts in solid wood.

✅ Cut with the Good Side Facing Down – Circular saws cut upward, meaning the top side of your material will have tear-out. If cutting plywood, keep the finished side facing down for a cleaner cut.

✅ Start Slow, Then Glide Smoothly – Don’t force the saw forward too quickly. Instead, let the blade reach full speed before smoothly pushing it along the guide.

✅ Keep the Saw Base Flat Against the Guide – If you tilt the saw even slightly, your cut will wander off-track. Always press the baseplate firmly against the straightedge.

✅ Make a Test Cut First – Before cutting an expensive piece of wood, run a test cut on scrap material to ensure the guide is set correctly.

➡ Pro Tip: For extra clean cuts in plywood, apply painter’s tape along the cut line to reduce splintering.

🚫 Common Mistakes to Avoid

🔴 Using a Warped Guide – If your DIY circular saw guide is slightly bent or warped, your cuts will never be straight. Always use high-quality plywood or aluminum for the straightedge.

🔴 Not Accounting for Blade Kerf – The kerf (thickness of the saw blade cut) can slightly reduce your final measurement. Always cut on the waste side of the line to avoid errors.

🔴 Neglecting to Secure the Workpiece – If the wood moves while cutting, you’ll lose accuracy and risk kickback. Use clamps or non-slip mats to keep everything steady.

🔴 Pushing Too Hard or Too Fast – Forcing the saw can bind the blade, create rough edges, or even cause dangerous kickback. Let the saw do the work and guide it with steady pressure.

🔴 Ignoring Safety Precautions – Always wear safety glasses, ear protection, and a dust mask. Circular saws can throw debris and make loud, high-pitched cuts that damage hearing over time.

➡ Pro Tip: Never lift the saw before the blade completely stops spinning—this prevents accidental kickback and tear-out.

🚀 Advanced Upgrades & Modifications

Want to take your DIY circular saw guide to the next level? Here are some powerful enhancements that will make your guide more accurate, versatile, and durable.

✔ Adjustable Fence for Different Blade Sizes – If you switch saws often, add an adjustable fence that can accommodate different saw baseplate widths.

✔ Ruler or Measuring Tape Integration – Attach a self-adhesive measuring tape to the guide for quick, repeatable cuts without needing to measure each time.

✔ Non-Slip Rubber Base – Apply rubberized grip strips under the guide so you don’t have to clamp it every time.

✔ Sliding Stop Blocks for Consistent Repetitive Cuts – If making multiple identical cuts, install adjustable stop blocks to speed up production.

✔ Foldable or Modular Design – Cut the guide into two sections with hinges to make it easier to store and transport.

Key Takeaways

✔ A DIY circular saw guide eliminates guesswork—follow the pro cutting techniques for perfect cuts every time.

✔ Avoid common mistakes like using warped materials, rushing the cut, or ignoring safety precautions.

✔ Upgrade your guide with non-slip bases, built-in rulers, or stop blocks for even more accuracy and efficiency.

Now that you know how to use your DIY circular saw guide like a pro, let’s explore store-bought options for those who prefer ready-made cutting guides.

Best Store-Bought Circular Saw Guides (Alternative Options)

Not everyone has the time or tools to build a DIY circular saw guide—and sometimes, a store-bought guide is the better choice. Whether you’re looking for ultimate precision, durability, or convenience, here are the best pre-made circular saw guides you can buy.

👉 All of the guides below are highly rated and available on Amazon, making them easy to order and start using right away.

1. Kreg Accu-Cut Circular Saw Guide

⭐ Best for: Long, precise cuts on plywood and sheet goods.

✔ Turns your circular saw into a precision track saw.

✔ 50-inch aluminum track for dead-straight cuts up to 4 feet long.

✔ Anti-slip guide strips hold the track in place—no clamps needed.

✔ Works with any standard circular saw (left or right-blade models).

➡ Why It’s a Great Alternative to a DIY Circular Saw Guide:

The Kreg Accu-Cut is perfect if you want the precision of a track saw without building your own guide. It’s foolproof for beginners and ensures perfectly straight cuts every time.

2. Bora WTX Clamp Edge Saw Guide

⭐ Best for: Budget-friendly straight cuts with a secure clamp system.

✔ Strong aluminum clamp edge keeps the guide locked in place.

✔ Available in 50-inch and 100-inch lengths for long rips and crosscuts.

✔ Expandable design—add track extensions for even longer cuts.

✔ Works with circular saws, routers, and jigsaws.

➡ Why It’s a Great Alternative to a DIY Circular Saw Guide:

If you need a simple, effective guide that clamps directly onto your workpiece, the Bora WTX Clamp Edge is a solid choice. It’s cheaper than a full track system while still ensuring straight, repeatable cuts.

3. Milescraft Universal Track Saw Guide

⭐ Best for: Budget-friendly cutting guide with multiple functions.

✔ Universal saw guide works with most circular saws.

✔ Allows for both straight and angled cuts.

✔ Compact and portable—great for small workshops.

✔ Affordable option for those on a tight budget.

➡ Why It’s a Great Alternative to a DIY Circular Saw Guide:

If you need a lightweight, portable saw guide that works with multiple tools, the Milescraft Saw Guide is a cost-effective solution.

4. Makita Guide Rail System

⭐ Best for: Makita circular saw and track saw users.

✔ Precision-machined aluminum rail for ultra-straight cuts.

✔ Anti-slip backing prevents movement during cuts.

✔ Compatible with Makita plunge saws and many circular saws with adapter.

✔ Available in 55-inch and 118-inch lengths.

➡ Why It’s a Great Alternative to a DIY Circular Saw Guide:

If you own a Makita circular saw or track saw, this guide rail system provides next-level accuracy—it’s as close as you can get to a professional-grade track saw.

5. DeWalt TrackSaw Guide (For DeWalt Track Saws)

🔗 View the DeWalt TrackSaw Guide Rail on Amazon

⭐ Best for: High-quality cuts with DeWalt saws.

✔ Works seamlessly with DeWalt TrackSaw and many circular saws.

✔ Non-slip grip and precision-machined track.

✔ Available in 46-inch and 102-inch sizes.

✔ Smooth glide action for professional results.

➡ Why It’s a Great Alternative to a DIY Circular Saw Guide:

DeWalt’s TrackSaw Guide Rail is a premium option for woodworkers and professionals who need precise, repeatable cuts.

6. Festool Track Saw Guide Rail System

⭐ Best for: High-end professional accuracy.

✔ Premium German-engineered track system for perfect cuts.

✔ Rubber edge strip for zero-tearout cuts.

✔ Available in multiple lengths (32″ to 197″).

➡ Why It’s a Great Alternative to a DIY Circular Saw Guide:

If you’re a serious woodworker or professional, the Festool Guide Rail System delivers industry-leading precision and build quality.

Key Takeaways

✔ DIY circular saw guides are cost-effective and customizable, but store-bought guides offer added convenience and precision.

✔ The Kreg Accu-Cut and Bora WTX are great all-around options for beginners and DIYers.

✔ If you use Makita or DeWalt saws, their track systems provide high-precision cutting.

✔ The Milescraft and Festool options cater to budget-conscious DIYers and high-end professionals.

Whether you build your own DIY circular saw guide or invest in a store-bought model, having a cutting guide will dramatically improve your woodworking accuracy and efficiency.

Up next, let’s tackle the most common questions about circular saw guides in the FAQ section.

DIY Circular Saw Guide FAQ (Frequently Asked Questions)

Why should I use a DIY circular saw guide instead of freehand cutting?

Freehand cutting with a circular saw is rarely accurate, especially for long cuts. A DIY circular saw guide ensures straight, precise cuts every time, eliminating wobbly edges and material waste while improving safety and efficiency.

Can I use a DIY circular saw guide for angled cuts?

Yes, but you’ll need to find your angle and clamp the guide accordingly or modify the design. For angled cuts:

✔ Use an adjustable fence or pivoting straightedge to guide your saw at different angles.

✔ Consider using a miter saw or track saw for perfect bevel cuts.

➡ Pro Tip: If you need frequent angled cuts, a Bora WTX Clamp Edge or Kreg Accu-Cut may be a better store-bought option.

What is the best material to use for a DIY circular saw guide?

The best materials are:

✔ 1/2-3/4 inch plywood (preferred) – Somewhat lightweight, sturdy, and resists warping.

✔ MDF (Medium-Density Fiberboard) – Smooth and straight but not as durable.

✔ Hardwood strip (maple, oak, poplar) – Best for a long-lasting, rigid straightedge.

➡ Avoid particle board or warped lumber, as these can lead to inaccurate cuts.

How do I keep my DIY circular saw guide from slipping?

To prevent slipping:

✔ Use clamps (Quick-grip or C-clamps work best).

✔ Add non-slip rubber strips to the bottom of the guide.

✔ Place double-sided tape under the guide for extra grip.

➡ If you want a clamp-free option, consider a Makita Guide Rail System, which features built-in grip strips.

Can I use any circular saw with a DIY circular saw guide?

Yes! Most DIY circular saw guides work with any standard circular saw. However, make sure that:

✔ The baseplate of your saw fits properly against the straightedge.

✔ Your saw blade is aligned correctly to match the guide’s cut line.

➡ If you switch saws, test the guide first to ensure the cut line stays accurate.

What’s the difference between a circular saw guide and a track saw system?

🔹 DIY Circular Saw Guide – A simple straightedge that keeps cuts straight. Cost-effective and easy to build.

🔹 Track Saw System – A professional-grade guide rail that provides zero-clearance precision with a built-in track for the saw.

➡ If you need perfect, high-end cuts, consider a Festool Guide Rail System or a DeWalt TrackSaw Guide Rail.

How do I store my DIY circular saw guide?

Store it flat and dry to prevent warping. Options include:

✔ Hanging it vertically on a wall with hooks.

✔ Storing it flat under a workbench.

✔ Using pegboard storage for easy access.

➡ For compact storage, a foldable guide design or a modular track system like the Bora WTX Clamp Edge is a great alternative.

Is a DIY circular saw guide worth it if I only make occasional cuts?

Absolutely! Even if you’re an occasional DIYer, a DIY circular saw guide will:

✔ Improve cutting accuracy for every project.

✔ Save wood by reducing mistakes and wasted material.

✔ Boost safety by keeping your hands farther from the blade.

➡ If you prefer a pre-made solution, consider the Milescraft Saw Guide—a budget-friendly, portable option.

Can I use my DIY circular saw guide for a jigsaw or router?

Yes, but make sure the baseplate fits correctly:

✔ A jigsaw may require a wider base for stability.

✔ A router may need extra clamping to prevent movement.

✔ Some store-bought guides, like the Kreg Accu-Cut, are compatible with multiple tools.

Final Thoughts

By now, you have everything you need to build, use, and upgrade your DIY circular saw guide. Whether you choose to make your own or buy a store-bought guide, the key takeaway is the same:

✔ A cutting guide dramatically improves accuracy, safety, and efficiency.

If you’re looking to improve your circular saw skills, check out these related guides:

🔗 How to Use a Circular Saw (Step-by-Step Guide) – Learn how to master setup, cutting techniques, and safety tips for better results.

🔗 How to Cut Wood Straight Every Time – Discover pro techniques for straight, precise cuts with any saw.

If you’re just getting into woodworking, these pillar posts will help you build a strong foundation:

🔗 DIY Woodworking for Beginners: Essential Skills & First Projects – The ultimate guide to starting your woodworking journey with confidence.

🔗 Best Woodworking Tools for Beginners (Must-Have List) – A complete list of essential tools every beginner needs.

Want more DIY woodworking tips? Subscribe to my email list for more in-depth guides, tool recommendations, and pro tips!

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!