DIY Woodworking for Beginners: Ultimate Guide to Getting Started In 2025

Disclosure: This post may contain affiliate links from online retailers, including Amazon. If you click a link and buy tools or supplies, I may earn a small commission—at no extra cost to you. This allows me to provide you free helpful content, and I genuinely appreciate your support🤝 Learn more

There’s nothing like creating something with your own two hands. I’ve worked in the construction trades for many years, building everything from custom homes to fine finish carpentry in Santa Barbara/Montecito, CA, for high-end clients. But woodworking for beginners? That’s where the passion truly is.

The satisfaction of turning raw materials into something useful is unmatched, and that’s why we’re here. To tackle DIY woodworking for beginners and help you build skills with confidence. Be sure to open my Woodworking & Carpentry hub to explore more as well!

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

If you’re eager to dive into woodworking for beginners but feel overwhelmed by tools, materials, and techniques, don’t worry. This guide will walk you through everything you need to get started, including:

✔️ Essential woodworking tools and how to use them

✔️ The best types of wood for beginners

✔️ Basic joinery techniques and woodworking terminology

✔️ Setting up a woodworking space (even if you don’t have a full workshop)

✔️ Safety practices to keep you injury-free

✔️ Step-by-step beginner woodworking projects to get you started

By the end of this guide, you’ll have the confidence to tackle your first projects in woodworking for beginners. So grab your tools, roll up your sleeves, and let’s get started!

WHY DIY Woodworking for Beginners is Awesome

Bear with me here before we dive into the meat and potatoes of woodworking and carpentry.

Woodworking isn’t just about making things, it’s about the joy of creating. There’s something deeply satisfying about transforming raw wood into a functional, handmade piece that reflects your personality and skill.

For those exploring woodworking for beginners, every project, whether it’s a rustic coffee table, a sleek floating shelf, or a hand-carved wooden sign, is an opportunity to develop craftsmanship and express creativity.

As you refine your techniques, woodworking for beginners becomes more than a hobby; it becomes a rewarding and practical skill that lasts a lifetime.

A Creative and Practical Outlet

Many hobbies are purely recreational, but woodworking for beginners is both artistic and practical. Not only do you get to design and customize pieces that match your style and space, but you also create things that serve a purpose.

Imagine building a sturdy workbench to help with future projects!

It’s a skill that enhances your home and everyday life. Whether you’re just starting out or looking to improve, DIY woodworking for beginners offers endless opportunities to create, learn, and refine your craftsmanship.

Affordable to Start, but an Exciting Journey of Progress

If I’m being honest, woodworking for beginners isn’t the cheapest hobby in the long run. Power tools, high-quality materials, and setting up a proper shop can get expensive fast.

But just getting started? That’s a different story. You don’t need a fully stocked workshop or high-end tools to begin.

A few basic hand tools, minimal power tools, some beginner-friendly wood, and a bit of determination are all it takes! Your first woodworking for beginners project can be built with a handsaw, a drill, clamps, and sandpaper. No table saw required!

Here’s The Exciting Part…

Once you’re hooked, you’ll want more tools, and that’s a good thing! Each new tool expands your skillset, opens up new project possibilities, and takes your craftsmanship to the next level.

Whether it’s upgrading to a circular saw for faster cuts, investing in a router for shaping edges, or eventually setting up a full woodworking shop, progression is part of the woodworking for beginners journey. And that’s where the real fun begins if you ask me.

At Tekton Travis, I’ll guide you every step of the way. My goal is to help you make smart tool investments, find the best deals, and level up your skills as a woodworker, carpenter, or DIYer.

Woodworking is a journey, and you don’t have to go it alone. Sign up for my email list to get exclusive beginner woodworking guides, tool reviews, build plans, and insider tips to help you progress. Whether you’re starting with your first woodworking for beginners project or upgrading your shop, I’ll help you every step of the way.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Nothing beats the feeling of standing back and saying, “I built this.” Even if your first woodworking for beginners project isn’t perfect (trust me, mine wasn’t either), the sense of accomplishment is unmatched. With every project, you’ll gain confidence, develop essential skills, and become more self-reliant. Woodworking for beginners isn’t just a hobby—it’s a lifelong skill that allows you to build, repair, and create with your own two hands.

Now let’s dive right in.

Understanding Different Types of Wood & Choosing the Right One

Before starting your first woodworking for beginners project, it’s important to choose the right wood. Some types are easy to work with and great for beginners, while others are more durable but require advanced skills. The wrong choice can lead to difficult cuts, poor finishes, or structural issues.

Let’s break down the best woods for woodworking for beginners and how to choose the right one for your project.

Common Wood Types for Beginners

Wood is generally classified into two main categories: softwoods vs. hardwoods. Each has unique properties that affect how easy they are to cut, shape, and finish.

Softwoods (Beginner-Friendly & Budget-Friendly)

Softwoods are widely available, easier to cut, and more affordable, making them ideal for first-time woodworkers.

- Pine – One of the best choices for beginners. It’s lightweight, easy to cut, and sands smoothly. Perfect for shelves, furniture, and DIY home projects.

- Cedar – Naturally resistant to moisture and insects, making it great for outdoor projects like planters or birdhouses.

- Fir – Strong but can be tricky to stain due to its uneven grain. Works well for framing, rustic furniture, and utility projects.

Hardwoods (Stronger, More Durable, But Harder to Work With)

Hardwoods are denser, more durable, and often more expensive. They require sharper tools and more effort to shape, but they last longer and look more polished.

- Oak – Extremely strong and durable, often used for furniture, cabinets, and flooring. Can be tough on beginner tools but provides a professional finish.

- Maple – One of the hardest woods. Ideal for cutting boards and workbenches because it resists dents and scratches.

- Walnut – A luxurious hardwood with a deep, rich color. Great for high-end furniture, decorative pieces, and tabletops. However, it’s expensive and harder to work with.

How to Choose the Right Wood for Your Project

When selecting wood, consider these key factors:

✔ Budget – Softwoods like pine and fir are cheaper, while hardwoods like oak and walnut cost more. If you’re just starting, stick with affordable woods until you’re comfortable investing in premium materials.

✔ Strength & Durability – Need strong, long-lasting furniture? Use hardwood. Building a simple wall shelf? Pine or cedar will do just fine.

✔ Finish & Appearance – If you plan to stain or paint your project, choose a wood that absorbs finishes well. Pine and oak take stain nicely, while fir can be blotchy.

✔ Workability – Hardwoods require sharper tools and more effort, while softwoods cut easily with basic tools. If you’re new, start with softwood and work your way up to hardwoods.

Choosing the right wood is one of the most important steps in woodworking. Start with softwoods like pine for simple projects, then progress to hardwoods as your skills improve.

🔨 Next up: Let’s talk about the essential woodworking terms & concepts you’ll want to know to build up your woodworking knowledge!

Related: Best Wood for DIY Projects (Beginner’s Ultimate Guide)

Basic Woodworking Terms & Concepts

Before diving into projects, it’s important to understand key woodworking terms. These concepts will help you follow tutorials, read plans, and communicate like a pro as you build your skills.

Essential Woodworking Terms

✔ Grain – The direction in which wood fibers run. Cutting with the grain results in smoother, cleaner cuts, while cutting against the grain can lead to tear-out. When sanding, always follow the grain for the best finish.

✔ Kerf – The width of the cut made by a saw blade. Every saw removes a small amount of wood as it cuts, so always account for kerf when measuring and making precision cuts.

✔ Tear-Out – When wood fibers splinter or chip along a cut edge. This often happens when cutting against the grain or using a dull blade. Using sharp tools, cutting slowly, and applying painter’s tape over the cut line can help prevent tear-out.

✔ Bevel – An angled cut along the edge of a piece of wood. Bevel cuts are commonly used for furniture edges, trim work, and decorative designs.

✔ Chamfer – Similar to a bevel, but instead of a smooth sloped edge, a chamfer creates a flat, angled surface that removes the sharp 90-degree edge of a board. Used for aesthetic detailing, safety, and edge softening.

✔ Dado – A rectangular groove cut across the wood grain, typically used in joinery for shelving, cabinets, and sturdy connections.

✔ Rabbet – A step-like groove cut along the edge of a board. Often used in cabinetmaking and box construction to create strong joints.

✔ Mortise & Tenon – A classic woodworking joint where a tenon (a rectangular tongue) fits into a mortise (a corresponding hole). This joint is known for its strength and durability, often used in furniture making.

✔ Miter – A cut made at an angle, usually 45 degrees, to join two pieces together for a seamless corner, such as in picture frames and trim work.

✔ Resawing – The process of cutting a thick board into thinner boards along its width, often done using a band saw or table saw to make thinner stock or book-matched pieces.

✔ Face, Edge, and End Grain –

- Face Grain – The largest, flattest surface of a board.

- Edge Grain – The long, narrow side of a board.

- End Grain – The exposed fibers on the short ends, which absorb glue and finishes differently than face or edge grain.

✔ Rip Cut – A cut made parallel to the grain of the wood. This is different from a crosscut, which goes across the grain.

✔ Crosscut – A cut made perpendicular to the grain of the wood. Best done with a miter saw, circular saw, or hand saw.

Understanding these terms will help you follow woodworking plans with confidence and make more precise cuts and joints in your projects.

Now that you’re familiar with the terminology, let’s break down the most common woodworking cuts and how to make them accurately.

Related: Basic Woodworking Terms for Beginners In 2025

Common Woodworking Cuts

Mastering different types of cuts is essential for building precise, high-quality woodworking projects. Whether you’re cutting boards for furniture, joinery, or decorative elements, knowing which cut to use will help you work more efficiently and accurately.

Essential Woodworking Cuts

✔ Crosscut – A cut made across the grain of the wood. This is one of the most common cuts and is used for sizing boards and making precise, square edges. Best done with a miter saw, circular saw, or hand saw.

✔ Rip Cut – A cut made parallel to the grain of the wood. This cut is used when you need to resize boards to a custom width. Best done with a table saw or circular saw.

✔ Miter Cut – An angled cut, usually 45 degrees, used to create seamless corners in projects like picture frames, trim, and molding.

✔ Bevel Cut – A cut made at an angle other than 90 degrees through the thickness of the board. Bevels are commonly used for furniture edges, decorative finishes, and joint reinforcement.

✔ Dado Cut – A rectangular groove cut into the face of a board, typically across the grain. Dadoes are used in cabinetry, bookshelves, and structural joinery to create sturdy, interlocking joints. Best done with a dado blade on a table saw or with a router.

✔ Rabbet Cut – A step-like groove cut along the edge of a board. Often used in cabinetry and drawer construction to create strong, flush joints.

✔ Lap Joint Cut – A cut where two boards partially overlap to create a strong and flush joint. Commonly used in furniture making and framework.

✔ Plunge Cut – A cut that starts in the middle of the wood rather than at the edge. Typically made using a router or jigsaw, ideal for creating openings or inlays in tabletops and panels.

✔ Resawing Cut – A cut made along the thickness of a board to create thinner boards or book matched pieces for paneling and veneering. Best done with a band saw.

✔ Cove Cut – A concave, curved cut often made using a router or a table saw with a cove-cutting jig. Used for decorative trim, molding, and artistic woodworking designs.

✔ Scarf Cut – A diagonal cut made along the ends of two boards to extend length while maintaining strength. Often used in trim work and structural joinery.

Understanding these common cuts will allow you to execute your projects with precision and confidence. Now that you know the basics, let’s dive into essential joinery techniques—the key to making strong, durable woodworking connections.

Also Check Out: Tools and Gear Hub

Beginner Joinery Techniques

Joinery is the method used to connect two or more pieces of wood securely. Strong joints are key to building durable furniture, cabinets, and frames. Here are some beginner-friendly to advanced techniques to get started:

Essential Joinery Methods for Beginners

✔ Butt Joint – The simplest and most basic joint where two pieces of wood are attached at 90 degrees using screws, nails, or glue. While not the strongest, it’s great for quick, simple builds.

✔ Pocket Hole Joinery – A beginner-friendly technique using angled pre-drilled holes and screws to create strong, hidden joints. Often used for table frames, bookshelves, and cabinetry.

✔ Dowel Joint – Uses wooden dowels and glue to reinforce a connection. Helps align boards and adds strength without visible screws. Commonly used in furniture and cabinetry.

✔ Mortise & Tenon – A classic, durable joint where a tenon (rectangular tongue) fits into a mortise (matching hole). This is one of the strongest joints used in high-end furniture and structural woodworking.

✔ Lap Joint – Two boards overlap partially to increase surface bonding. A great mid-level strength joint commonly used in frames and table bases.

✔ Half-Lap Joint – A variation of the lap joint where half the thickness of each board is removed, creating a flush and sturdy connection. Used in furniture frames and structural projects.

✔ Bridle Joint – Similar to a mortise and tenon but with an open-ended slot, making it easier to fit together. Used in frames and furniture.

✔ Biscuit Joint – Uses oval-shaped wooden biscuits and glue to reinforce a seam between two boards. Ideal for tabletops, cabinet panels, and furniture.

✔ Tongue & Groove Joint – One board has a ridge (tongue) that fits into a slot (groove) on another board. Commonly used in flooring, paneling, and door construction.

✔ Spline Joint – A thin strip of wood (spline) is inserted into a groove cut into two boards, strengthening the joint while keeping it aligned. Often used for tabletops and box-making.

✔ Box Joint – A series of square, interlocking cuts that fit together like puzzle pieces. Offers strong connections without nails or screws, often used in drawer construction and decorative boxes.

Mastering joinery is essential for creating strong, long-lasting woodworking projects. Start with butt joints and pocket holes, then progress to dowel, mortise & tenon, and other advanced techniques as your skills grow.

Now, let’s explore the most essential woodworking tools that will make these joints possible to create!

Most Essential & Common Woodworking Tools

Essential Woodworking Hand Tools for Beginners

While power tools speed things up, hand tools offer precision and control, making them an important part of any woodworker’s setup. Here are the most essential hand tools to get started:

✔ Claw Hammer – A staple tool for driving and removing nails in woodworking projects.

✔ Chisels – Used for cleaning up joints, carving details, and refining edges. A good starter set includes ¼-inch, ½-inch, and 1-inch chisels.

✔ Hand Saw – A reliable, non-powered cutting tool. A Japanese pull saw is excellent for making precise, clean cuts.

✔ Block Plane – Ideal for smoothing rough edges, trimming doors, and fine-tuning joints.

✔ Combination Square – Ensures perfectly accurate 90-degree and 45-degree angles for layout and cutting.

✔ Tape Measure – Accuracy is everything. A sturdy tape measure ensures your cuts and layouts are precise. Here are the best tape measures you can get.

✔ Marking Gauge – Helps create repeatable, accurate lines for cuts and joinery.

✔ Mallet – Used for chiseling and assembling joints without damaging the wood.

✔ Clamps – A must-have for gluing, cutting, and drilling. You’ll quickly learn: you can never have too many clamps!

Read All Related to Hand Tools

Essential Woodworking Power Tools for Beginners

While hand tools provide control and craftsmanship, power tools speed up the process and improve accuracy. Here are the most important power tools for woodworkers:

✔ Circular Saw – One of the most versatile tools for woodworking. Used for straight cuts in lumber, plywood, and sheet goods. Knowing how to use a circular saw is essential.

✔ Jigsaw – Perfect for cutting curves and irregular shapes in wood. A must-have for decorative projects and furniture details. You should definitely learn how to use a Jigsaw.

✔ Table Saw – The centerpiece of most woodworking shops. Ideal for making precise rip cuts, crosscuts, and joinery cuts.

✔ Miter Saw – Best for accurate angled cuts, making it essential for frames, trim, and precise joinery.

✔ Router – Used for shaping edges, cutting dadoes, rabbets, and decorative molding. One of the most versatile tools in woodworking. Dive deeper here.

✔ Power Drill & Impact Driver – Essential for drilling holes and driving screws efficiently. The impact driver makes screw driving easier, especially with hardwoods.

✔ Random Orbital Sander – A must-have for smoothing surfaces quickly and evenly. It helps create a professional, finished look before staining or painting. You need to know how to use an orbital sander.

✔ Band Saw – Great for curved cuts, resawing lumber, and intricate details. Unlike a jigsaw, it offers more control and precision.

✔ Track Saw – A more precise alternative to a circular saw, especially for breaking down large sheets of plywood and the best way to cut wood straight.

✔ Drill Press – Offers more accuracy than a handheld drill, making it great for precise hole drilling and repetitive cuts.

A combination of hand tools and power tools will allow you to tackle any woodworking project.

Start with essential hand tools, then invest in power tools as your projects and skills become more advanced.

🔨 Next up: Let’s talk about setting up your first woodworking space!

Setting Up Your First Woodworking Space

Now that you have the right tools, it’s time to set up a functional and safe woodworking space. You don’t need a massive workshop to get started.

Many woodworkers begin in a garage (like me), basement, or even a small corner of a room. What matters most is organization, safety, and efficiency.

Beginner Woodworking Workspace Setup

✔ Flat, Sturdy Work Surface – A solid workbench or sturdy table is essential for cutting, assembling, and finishing projects. If space is tight, consider a folding workbench or a portable table. Having a reliable workspace is a key foundation in woodworking for beginners.

✔ Good Lighting – Proper lighting helps prevent mistakes and improves safety. Garage shop lights, LED work lights, or a well-lit window are great options. A well-lit space is especially important when getting started in woodworking, because it helps with precision when measuring and cutting.

✔ Storage for Tools – Keep tools organized and within reach using pegboards, a French cleat system, wall-mounted shelves, tool chests, or rolling carts. Staying organized will make your woodworking for beginners journey smoother and more enjoyable.

✔ Ventilation & Dust Collection – Wood dust is a health hazard. If possible, work near a window, install a dust collection system, or use a shop vac to minimize airborne dust.

✔ Clamping Area – Secure workpieces with clamps or vises to ensure safer, more accurate cuts. A sturdy clamp setup is crucial for gluing, sanding, and assembly.

✔ Noise & Ear Protection – Power tools can be loud. Use ear protection like earmuffs or earplugs to prevent hearing damage.

✔ Fire Safety – Always have a fire extinguisher nearby, especially when working with sawdust and flammable finishes.

✔ Proper Electrical Setup – Woodworking tools require power. Make sure your workspace has enough outlets and surge-protected extension cords to safely handle your tools.

✔ Workbench Height & Comfort – A comfortable workbench height (34-38 inches for most people) prevents back strain and makes working easier. Here are some versatile workbench plans. And here’s a guide on how to build a simple one.

✔ Portable or Mobile Workstation – If you don’t have a dedicated shop, consider a mobile workbench, folding tables, or tool storage on wheels for easy setup and cleanup. (Check out my workbench plans above).

✔ Lumber & Material Storage – Store lumber horizontally on racks to prevent warping and keep offcuts organized for future use. Build some DIY storage shelves!

Common Mistakes to Avoid

🚫 Not Securing Workpieces Properly – Cutting or drilling unstable wood can lead to accidents and imprecise work. Always clamp your pieces down.

🚫 Ignoring Dust Control – Wood dust can be hazardous. Use a shop vac, dust collector, or wear a dust mask when cutting, sanding, or finishing wood.

🚫 Using a Cluttered Space – A messy work area is dangerous and inefficient. Keep your space organized and free of tripping hazards.

🚫 Poor Lighting – Bad lighting leads to mistakes and safety hazards. Position work lights near cutting areas for better visibility.

🚫 Neglecting Safety Gear – Not using ear protection, safety glasses, or gloves can cause long-term damage or injury. Always gear up before working.

Setting up a functional woodworking space will increase efficiency, improve accuracy, and keep you safe. Start with a simple, organized setup, then upgrade as you take on bigger projects.

🔨 Next up: Let’s go over essential woodworking safety practices to keep you injury-free and confident in your work!

Woodworking Safety Best Practices

Woodworking is incredibly rewarding, but it comes with real risks if you’re not careful. I’ve had my fair share of close calls, from getting debris in my eye to feeling the long-term effects of loud tools on my hearing. The truth is, ignoring safety isn’t worth it.

When you’re new, you might think, “I don’t need glasses just to make a quick cut,” or “Earplugs? I’ll be fine.”

But trust me, one flying wood chip to the eye is all it takes to make you rethink that decision. Here’s what I’ve learned the hard way and what you should always keep in mind.

Essential Safety Practices Every Woodworker Should Follow

✔ Wear Safety Glasses (ALWAYS!) – I once had a tiny piece of wood debris hit my eye while sanding because I skipped my glasses for “just a minute.” It’s ALWAYS painful, annoying, and not worth it. Since then, I have been diligent about my eye protection. In woodworking for beginners, getting into the habit of wearing safety gear early will prevent injuries down the road.

✔ Use Hearing Protection – Power tools are LOUD, and over time, they take a toll on your hearing. I used to think, “Eh, it’s just a few cuts” until I noticed my ears ringing after long shop sessions. Now, I always use earplugs or earmuffs. Woodworking for beginners involves loud tools like circular saws and routers, so protecting your ears from the start is key. Hearing damage is irreversible, so protect your ears early.

✔ Skip Gloves—Unless Necessary – Gloves can be more dangerous than helpful when using rotating tools like saws and drills, in my experience. They can get caught in moving blades, pulling your hand in before you even react. I personally dislike wearing gloves unless I’m handling really rough material, staining, or applying finishes. For anyone getting started with woodworking for beginners, learning when to wear gloves (and when not to) can make a big difference in safety.

✔ Use Push Sticks & Push Blocks – When using a table saw, jointer, or router table, never guide wood with your bare hands close to the blade. Push sticks keep your fingers safe while maintaining control. In woodworking for beginners, forming good habits like using push sticks early will help you avoid serious injuries.

✔ Keep Fingers Away from Moving Blades – Sounds obvious, right? But accidents happen when you get too comfortable. Always double-check your hand placement before making a cut. This is one of the most critical safety tips for woodworking for beginners, as many injuries happen when people assume they have complete control over a moving blade.

✔ Clamp Workpieces Securely – Cutting or drilling wood that isn’t securely clamped can lead to kickback, slipping, or jagged cuts. A stable workpiece is a safe workpiece. Many mistakes in woodworking for beginners come from not securing the workpiece properly, leading to uneven cuts and potential injury.

✔ Avoid Loose Clothing & Jewelry – Anything dangling near a spinning blade is a serious hazard. Keep sleeves rolled up and remove rings, watches, or necklaces before starting. For those new to woodworking for beginners, dressing properly for the shop is just as important as learning how to use tools correctly.

✔ Work in a Well-Ventilated Area – Stains, finishes, and wood dust can be hazardous if inhaled. Always work near an open window, install a dust collection system, or wear a respirator when handling chemicals. In woodworking for beginners, dust control and ventilation often get overlooked, but they are crucial for long-term health and safety.

✔ Keep Your Workspace Clean & Organized – A cluttered shop is a dangerous shop. Tripping over tools, stepping on wood scraps, or knocking something into a spinning saw blade can turn a simple job into an emergency. One of the best habits in woodworking for beginners is keeping your work area tidy to prevent accidents.

✔ Know How to Handle Kickback – Kickback happens when wood gets caught on a blade and shoots back toward you at high speed. It’s one of the leading causes of woodworking injuries. Use a riving knife and anti-kickback pawls on your table saw, and always stand to the side of the blade—never directly behind it. Woodworking for beginners involves learning how to control your tools properly, and understanding kickback prevention is essential.

✔ Unplug Power Tools Before Changing Blades – Never assume a tool is off just because the switch is in the off position. Unplug it before swapping blades, bits, or making adjustments. Safety should always be the top priority in woodworking for beginners, and developing this habit early will prevent accidental starts.

✔ Fire Safety – Wood dust and rags soaked in stain or oil can spontaneously combust if not stored properly. Always have a fire extinguisher nearby, and dispose of oily rags in a sealed metal container. Fire safety is often overlooked in woodworking for beginners, but knowing how to handle and store flammable materials can prevent serious hazards.

Related: Here are some of the best safety tips.

Common Woodworking Safety Mistakes Beginners Make

🚫 Skipping Safety Glasses “Just for a Second” – That’s all it takes for debris to fly into your eye. Always wear them.

🚫 Not Using Hearing Protection – If your ears are ringing after working in the shop, you’re already damaging your hearing.

🚫 Reaching Over a Running Blade – Never reach for a cut-off piece while the blade is still spinning. Let the tool stop first.

🚫 Not Respecting the Table Saw – The table saw is one of the most dangerous tools in the shop. Use a push stick, stand to the side, and always be mindful of kickback.

🚫 Leaving Clutter Around the Workspace – Tripping hazards increase your risk of accidents and make it harder to work efficiently.

🚫 Rushing Through Cuts – Slow, controlled movements lead to safer, cleaner cuts. Woodworking is not a race.

Safety might seem like a hassle at first, but once you’ve had debris hit your eye or ears ring from power tools, you’ll realize it’s non-negotiable. Take the time to develop safe habits now, and you’ll avoid painful mistakes down the road.

🔨 Next up: Let’s go over common beginner woodworking mistakes and how to avoid them!

Common Beginner Mistakes & How to Fix Them

Every woodworker makes mistakes, especially when starting out with woodworking for beginners. The key is learning from them so you can improve with every project. Here are some of the most common beginner mistakes and how to fix them.

🚫 Crooked Cuts – A wobbly cut can throw off an entire project. Use a guide rail, fence, or clamp a straight edge to ensure precise, straight cuts every time.

🚫 Screws Splitting Wood – Driving screws directly into wood can cause splitting, especially in softwoods. Always drill pilot holes first to prevent cracks and get a stronger hold.

🚫 Wood Glue Not Holding – Weak glue joints usually happen when pieces aren’t clamped properly. Clamp pieces tightly for at least 30 minutes and let the glue cure fully (24 hours for max strength) before stressing the joint.

🚫 Uneven Stain Absorption – Some woods absorb stain unevenly, resulting in blotchy finishes. Apply a wood conditioner before staining to help create a uniform color.

🚫 Wobbly Furniture – If your furniture rocks back and forth, your cuts weren’t square. Use a combination square to check corners and adjust as needed before assembly.

🚫 Measuring Mistakes – One of the biggest frustrations in woodworking for beginners is cutting pieces that don’t fit. Follow the golden rule: Measure twice, cut once. Using a marking knife instead of a pencil also improves accuracy.

🚫 Over-Sanding – Sanding too aggressively can round over edges that should be sharp or create dips in a flat surface. Start with coarse grit (80-120), then work up to 220 without applying too much pressure.

🚫 Ignoring Wood Movement – Wood expands and contracts with humidity. If you don’t account for this, panels can crack or warp over time. Leave small expansion gaps in panel designs and avoid gluing solid wood across the grain.

🚫 Not Letting Glue Dry Fully – If you rush and remove clamps too soon, joints will be weak. Let glue set for at least 30 minutes in clamps and avoid stressing joints for 24 hours.

🚫 Skipping Test Fits – Assembling without checking for alignment leads to gaps and misalignment. Always dry-fit pieces before gluing or fastening to make sure everything fits properly.

🚫 Using the Wrong Saw for the Job – Trying to rip cut with a jigsaw or crosscut with a table saw results in rough, imprecise cuts. Learn which saw works best for each type of cut.

🚫 Skipping Finishing Prep – Not sanding properly or applying stain in a dusty area can ruin a project’s final look. Always sand thoroughly, remove dust, and finish in a clean workspace.

Mistakes are part of the learning process, but knowing how to avoid them will speed up your progress and improve your results. Now that you know what not to do, let’s move on to wood finishing before some exciting projects you can apply all of this knowledge to!

Related: 14+ Common Woodworking Mistakes (And How to Avoid Them!)

Wood Finishing Basics

A great project for woodworking for beginners isn’t finished until… well, it’s finished!

Applying a proper finish protects the wood, enhances its beauty, and prevents wear over time. Skipping this step can lead to warping, cracking, or an unfinished look. Here’s how to finish wood the right way as a beginner.

Step 1: Sanding (The Foundation of a Smooth Finish)

✔ Start with 80-120 grit sandpaper to remove rough spots and imperfections.

✔ Work up to 220 grit for a smooth, polished surface.

✔ Wipe down the wood with a tack cloth or damp rag to remove dust before applying any finish.

Step 2: Staining (Adding Color & Depth)

✔ Choose a stain that complements the natural wood grain.

✔ Apply with a lint-free cloth or brush, wiping off excess to avoid blotches.

✔ For softwoods like pine, use a wood conditioner first to ensure even absorption.

Step 3: Sealing (Protecting the Wood)

✔ Polyurethane – Most durable, great for furniture and floors.

✔ Shellac – Provides a natural, classic finish, often used in traditional woodworking.

✔ Danish Oil or Tung Oil – Gives wood a soft, rich finish while soaking into the grain.

Step 4: Painting (For a Bold or Custom Look)

✔ Prime first for the best adhesion, especially on softwoods.

✔ Apply multiple thin coats of paint, letting each dry before adding another.

✔ Finish with a clear topcoat for protection against wear.

Finishing wood isn’t just about looks, it’s also about durability. A well-applied finish will protect your projects for years while giving them a professional touch. Start simple, experiment with different finishes, and find what works best for your style.

Related: How to Sand and Finish Wood: 7 Pro Tips for a Perfect Finish

🔨FINALLY! Last up: Let’s put everything you’ve learned into action with beginner-friendly woodworking projects!

Step-by-Step Woodworking For Beginners Projects

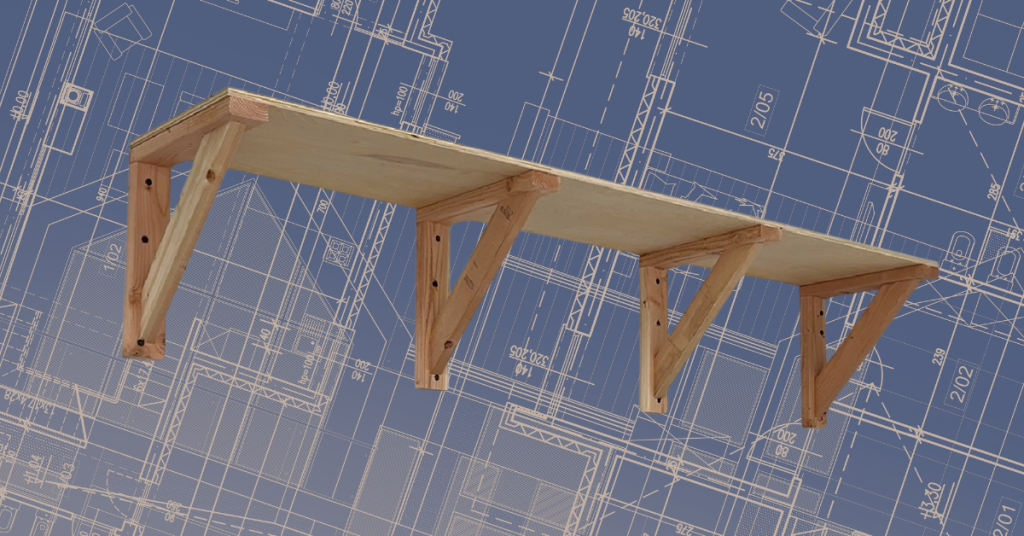

1. DIY Shelves

If you’re looking for a sturdy and functional shelving solution, these DIY garage shelves are the perfect project. They’re strong enough to hold heavy storage bins, cost-effective compared to store-bought shelves, and customizable to fit your space. This project will teach you essential cutting, fastening, and structural assembly techniques.

For a detailed step-by-step guide with pictures, check out my full tutorial here: How to Build DIY Garage Shelves.

Materials & Tools Needed

✔ 2×4 boards (for shelf frame and vertical supports)

✔ Plywood or OSB panels (for shelf surfaces)

✔ Wood screws (2 ½” or 3”)

✔ Drill and impact driver

✔ Level (to ensure even installation)

✔ Tape measure and pencil

✔ Circular saw or miter saw

✔ Clamps (optional, but helpful for assembly)

Step-by-Step Instructions

Step 1: Plan & Measure Your Space

- Decide how wide, tall, and deep your shelves need to be. Measure your space and determine how many shelves you want.

- A good depth for garage shelves is between 16-24 inches to accommodate storage bins.

Step 2: Cut the Frame & Shelf Supports

- Cut 2x4s for the vertical supports (legs)—these will determine your shelf height.

- Cut horizontal 2x4s for the front and back of each shelf level.

- Cut cross supports for added strength if spanning longer distances.

Step 3: Assemble the Shelf Frames

- Lay out the front, back, and side 2x4s to form a rectangular shelf frame.

- Secure with 2 ½” or 3” screws, making sure each corner is square.

- If your shelves are wide, add cross supports every 24 inches for extra stability.

Step 4: Install Vertical Supports & Secure to the Wall

- Position your vertical support posts against the wall (or freestanding if desired).

- Secure the back of the shelf frame into wall studs with lag screws for extra strength.

- Attach the remaining shelves at your preferred spacing.

Step 5: Attach the Shelf Surfaces

- Place plywood or OSB panels on top of the frames.

- Secure with wood screws every 8-12 inches along the edges.

- Sand edges for a clean finish.

Pro Tips

✅ For heavy-duty storage, use thicker plywood (¾” instead of ½”).

✅ Always secure shelving to wall studs if possible—this prevents failure that WILL happen eventually if secure only to the drywall.

✅ If storing extremely heavy items, add extra supports.

✅ I always overbuild rather than under build, it’s saved me more than a few times…

These DIY garage shelves are a strong, budget-friendly storage solution and a great beginner-friendly build.

For more details, including photos and additional customization tips, check out the full guide here: How to Build DIY Garage Shelves.

Now that you’ve mastered shelving, let’s move on to the next woodworking project!

2. Rustic Wooden Crate

A rustic wooden crate is a versatile beginner project that teaches you the basics of cutting, assembling, and finishing wooden structures. This crate can be used for storage, home décor, or even as a planter box.

This design follows the specifications of roughly 14” W x 34” L x 8” H with butt joints in the corners, glued and pin-nailed or screwed.

(Optional) You can add a decorative trim around the top perimeter with corner trim pieces to hide joints but feel free to get creative!

Materials & Tools Needed

✔ (7) 1×4 boards, 32” long (for front, bottom, and back panels)

✔ (4) 1×4 boards, 14” long (for side panels)

✔ (4) 1×2 trim boards, *wait to measure (optional top trim)

✔ (4) 1×1 boards, *wait to measure (inside structure supports)

✔ Wood glue (for extra strength)

✔ Pin nails or 1 ¼” wood screws

✔ Clamps (for securing during assembly)

✔ Sandpaper (120-220 grit) (for smoothing edges)

✔ Stain or paint (for finishing)

✔ Drill and/or nail gun

✔ Tape measure & pencil

Step-by-Step Guidelines

Be sure to double-check the measurements! Wood material varies widely! A typical 1×4 actually measures 3/4″ x 3 1/2″ most of the time…

Step 1: Cut the Wood Pieces

- Measure and cut (7) 1x4s at 32” for the bottom, front, and back panels.

- Measure and cut (4) 1x4s at 14” side panels.

- Sand all edges with 120-grit sandpaper, then finish with 220-grit for a smooth surface.

Step 2: Assemble the Crate Frame

- Apply wood glue along the edges of a 14″ side panel.

- Position a 32″panel flush against the side panel to form a butt joint at the corner. *Keep track of the orientation of the butt joint and be consistent throughout. See image below.

- Secure with pin nails or screws (pre-drill if using screws) at the corner. This will form a “L” with one front or back panel and a side panel.

- Do this 3 more times to get 4″Ls” that are the height of the 1x4s.

- Attach only 2 of the “Ls” to create a single rectangle then let’s move on.

Step 3: Attach the Bottom Panels

- Apply wood glue to the edges of one rectangle frame.

- Place 3 32″ bottom panels together on the inside portion of an “L”. Make sure it is flush (inline) with all edges. Trim where necessary.

- Secure with pin nails or screws around the perimeter of the “L” and repeat with another “L” to create a small incomplete box.

- Be sure to secure ALL the bottom panels around the perimeter.

- Now we will add the completed rectangle on top of the rectangle with the bottom attached. Be sure all the edges are flush and measure the height of the inside corners.

- Cut the 4 corner supports, which should be around 7″ flush to the top.

- Add glue and secure them from the outside.

Step 4 (Optional): Add Decorative Trim

- Measure the top perimeters to get the length of your trim pieces. (Don’t forget the thickness of the trim! The sides should be 14″ish and the front/backs should be 36″ish to account for the side trim thickness on each side.) How you oriented the butt joints with dictate the measurements.***

- Cut and attach the trim boards to the side panels.

- Double-check your outside measurement then cut and attach the side trim boards using wood glue and nails/screws.

- Finally, measure the overall length from the outside edges of the side trim pieces you put in and cut and install.

Step 5: Sand & Finish

- Sand the entire crate with fine-grit sandpaper (220-grit).

- Apply stain or paint based on your preference. For a rustic look, use dark stain and distress the edges slightly.

- Let the finish dry completely before using.

Pro Tips

✅ Clamping is key! Keep everything aligned while nailing or screwing.

✅ Pre-drill screw holes to prevent wood from splitting.

✅ For a more rustic look, lightly sand edges after staining for a worn-in appearance.

This beginner-friendly project teaches you cutting, joining, and trim work, while also producing a functional and stylish wooden crate.

*Like these pictures? Subscribe to my email list for other awesome guides!

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

3. Small Coffee Table

This versatile piece functions as both a coffee table and a bench, making it ideal for small spaces like apartments, condos, or cottages. With a simple yet sturdy design, it provides storage underneath while maintaining a clean, modern look. This project is a great introduction to woodworking for beginners, teaching essential skills like cutting, pocket hole joinery, and finishing techniques—perfect for those looking to build their skills and confidence.

For full build plans and additional diagrams, check out the original project guide from Kreg Tool here: Simple Small Space Coffee Table / Bench.

I recommend picking up a pocket hole jig like this one from Kreg Tool👇. I also think this one is a good one from Vevor if you’re on a budget.

Materials & Tools Needed

✔ (3) 2×2 boards (96” long) – for legs and spans

✔ (1) Laminated Panel (3/4” x 16” x 96”) – for shelf and top

✔ Pocket Hole Screws (32) 2 ½” – for frame assembly

✔ Pocket Hole Screws (28) 1 ¼” – for shelf and top

✔ Wood Glue – for added strength

✔ Wood Stain/Finish – optional, for final finishing

✔ Pocket-Hole Jig

✔ Circular Saw or Miter Saw

✔ Drill/Driver

✔ Measuring Tape & Pencil

✔ Clamps

✔ Sandpaper (120-220 grit)

Step-by-Step Instructions

Step 1: Cut & Prep Your Lumber

- Measure and cut all pieces according to the cutting list.

- Sand all boards to remove rough edges and prepare for assembly.

Step 2: Drill Pocket Holes

- Use a pocket-hole jig to drill holes in the following locations:

- Each end of the side spans.

- Each end of the width spans.

- Along the edges of the shelf piece.

- On the underside of the top piece for attaching to the frame.

Step 3: Assemble the End Frames

- Lay two legs parallel on a flat surface.

- Position a side span at the top and another 3 inches from the bottom.

- Ensure pocket holes face inward or downward to remain hidden.

- Apply wood glue to joints, clamp, and secure with 2 ½” pocket hole screws.

- Repeat to create the second end frame.

Step 4: Connect the End Frames

- Position both end frames upright.

- Attach the width spans between them at the top and bottom, forming a rectangular frame.

- Ensure all pocket holes are hidden or face downward.

- Apply wood glue, clamp, and secure with 2 ½” pocket hole screws.

Step 5: Install the Shelf

- Place the shelf inside the frame, resting on the lower width spans.

- Ensure it’s centered and flush with the top of the lower spans.

- Secure the shelf using 1 ¼” pocket hole screws through the pre-drilled holes.

Step 6: Attach the Top

- Position the top piece on the frame, ensuring equal overhang on all sides (about 2” on the length and ¼” on the width).

- Secure the top to the frame using 1 ¼” pocket hole screws through the pre-drilled holes on the upper width spans.

Step 7: Finish Up

- Fill any visible screw holes or imperfections with wood filler.

- Sand the entire piece for a smooth finish.

- Apply your choice of wood stain or paint, followed by a protective finish if desired.

Pro Tips

✅ Clamp pieces together before screwing to keep everything aligned.

✅ Pre-drill holes to prevent splitting when working with pocket holes.

✅ Use a stain that complements your space for a polished final look.

This DIY coffee table/bench is a great way to practice precision cuts, pocket hole joinery, and finishing techniques. It’s beginner-friendly yet produces a professional-looking piece you’ll actually use. For a detailed guide and build plans, visit: Simple Small Space Coffee Table / Bench.

Now that you’ve built your coffee table, let’s move on to your next woodworking project here!

Final Thoughts

Woodworking for beginners is one of the most rewarding and practical skills you can develop. Whether you’re building shelves for storage or crafting custom furniture, every project helps you hone your craftsmanship, improve problem-solving skills, and create something truly your own.

If you’re just getting started with woodworking for beginners, don’t overcomplicate it. Pick a project, gather your tools, and start cutting! Mistakes will happen, but that’s part of the learning process. With each build, you’ll gain confidence, refine your technique, and discover new skills.

At Tekton Travis, I’m here to help you along the way. From step-by-step build guides to tool recommendations and expert tips, I want to make sure you have everything you need to succeed in DIY woodworking for beginners.

👉 For exclusive woodworking plans, tool reviews, and expert advice, subscribe to my email list below.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Woodworking For Beginners Frequently Asked Questions

What are the essential tools I need to start woodworking?

As a beginner, start with basic hand tools such as a hammer, measuring tape, handsaw, chisels, and screwdrivers. As you gain experience, you can invest in power tools like a drill, circular saw, and sander to expand your capabilities. Read More here.

Which type of wood is best for beginners?

Softwoods like pine and cedar are excellent choices for beginners due to their affordability and ease of use. These woods are softer and more forgiving, making them ideal for practicing cutting and shaping techniques.

How can I set up a woodworking space if I don’t have a dedicated workshop?

You can create a functional workspace in a garage, basement, or even a small corner of a room. Ensure you have a sturdy workbench, proper lighting, and storage for your tools. Keeping your space organized will enhance safety and efficiency.

What safety measures should I follow while woodworking?

Always wear safety gear, including goggles, hearing protection, and a dust mask. Keep your work area clean to prevent accidents, and ensure you understand how to properly use each tool before starting a project.

Are there any beginner-friendly woodworking projects I can start with?

Yes, simple projects like building a birdhouse, picture frame, or bookshelf are great for beginners. These projects help you practice measuring, cutting, and assembling, allowing you to develop foundational skills before moving on to more complex tasks.