How to Build DIY Garage Shelves (7 Easy Steps + Diagrams)

Disclosure: This post may contain affiliate links from online retailers, including Amazon. If you click a link and buy tools or supplies, I may earn a small commission—at no extra cost to you. This allows me to provide you free helpful content, and I genuinely appreciate your support🤝 Learn more

Want to build sturdy DIY garage shelves without spending a fortune? Whether you’re tired of clutter piling up or just need better organization, building your own shelves is one of the easiest and most affordable ways to maximize your garage space.

In this step-by-step guide, I’ll show you exactly how to build strong, durable garage shelves using basic tools and materials. No complicated joinery or expensive lumber—just a practical, beginner-friendly build that you can easily complete in a weekend.

I’ve built countless shelves over the years, both for my own projects and professionally, so I’ll also share my best tips, mistakes to avoid, and cost-saving tricks along the way. Want a complete woodworking basics guide? Check that out here to help you along this project!

Let’s get started!

Why Build Your Own DIY Garage Shelves?

- ✅ Stronger than store-bought shelves – Custom-built to hold heavy tools & storage bins

- ✅ Cheaper DIY alternative – Save money with basic materials

- ✅ Custom-fit for your space – Adjust size & height to meet your needs

DIY Garage Shelves Project Overview

🛠 Skill Level: Beginner-Friendly

⏳ Time Required: 1–2 hours per shelf

💲 Estimated Material Cost: $20–$40+ per shelf (it depends on what wood you buy).

👉 Building DIY garage shelves is simple! Cut your 2x4s, assemble sturdy brackets, mount them to wall studs, and secure plywood shelves. Follow this detailed guide for the exact steps!

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Materials & Tools You’ll Need

Head to the Home Depot, Ace Hardware, Lowes, or local lumber yard and pick up whatever material you need for these DIY garage shelves.

Materials:

| Material | Quantity | Purpose |

|---|---|---|

| 2 × 4 x 8ft Douglas fir boards | 4 (just to be safe) | Shelf brackets and supports |

| 4′ x 8’x ¾-inch plywood of your choice | 1 sheet | Shelf surface |

| 1 5/8-inch wood screws | 1 box | Attaching plywood to supports |

| 3-inch wood screws | 1 box | Assembling shelf supports |

| 3½-inch SDS screws | 8+ or small box | Mounting to wall studs |

Tools:

| Tool | Purpose |

| Miter saw (optional) | Cutting wood accurately |

| Speed Square | Mark square and 45 degree cut lines |

| Drill/driver | Driving screws |

| Circular saw (How-to guide for beginners) | Cutting plywood shelves |

| Stud finder, magnet or | Locating wall studs |

| Level | Ensuring level and straight installation |

| Measuring tape | Accurate measurements |

🔗Related Posts To Help:

➡️17 Best Woodworking Tools for Beginners (Budget & Pro Picks!)

➡️Essential Power Tools for Beginners: DIY In 2025

Step 1: Plan Your Shelf Dimensions

Before making any cuts, you need to plan the right dimensions based on your garage space and storage needs. Taking the time to measure correctly now will prevent frustration later and ensure your shelves fit perfectly.

📏Decide Your Shelf Size

Here are some recommended dimensions based on common garage storage needs:

| Storage Type | Recommended Depth | Recommended Width | Recommended Height |

|---|---|---|---|

| General Storage (tools, bins) | 16″ – 24″ | 4′ – 8′ | 6′ – 7′ |

| Heavy-Duty Storage | 24″ – 30″ | 4′ – 8′ | 6′ – 8′ |

| Wall-Mounted Shelves | 12″ – 18″ | Custom | Mounted 2′ – 4′ apart |

Pro Tip: 🛠 If you plan to store large plastic bins, make sure the depth of your shelves allows them to fit without overhanging. Measure the bins first, then choose your shelf depth accordingly.

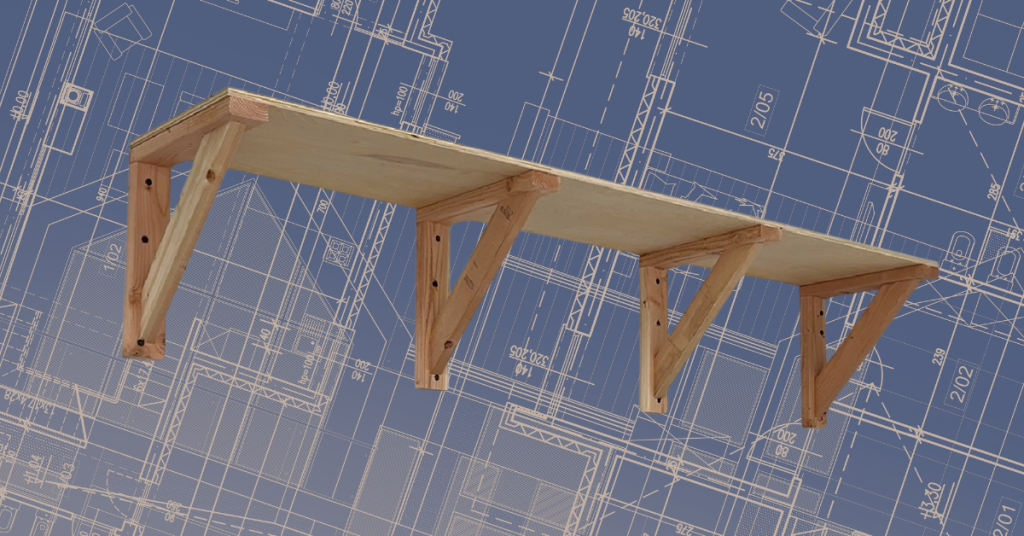

For this guide, we will build a single garage shelf that is 8 feet wide and 19 inches deep to fit standard storage bins. But you can build whatever size DIY garage shelves you need of course.

Key Measurements for Our DIY Garage Shelves:

For this guide, we will be building a single garage shelf that is:

✔ 8 feet wide (to maximize plywood usage with 8ft sheets)

✔ 19 inches deep (perfect for standard storage bins)

✔ Adjustable height (customizable to fit your storage needs)

🔍 Planning for Larger Shelves? Here’s How:

✔ Need a wider shelf? Use a 10′ plywood sheet for a 10′ wide shelf.

✔ Want a massive 16′ shelf? Join two 8′ sheets together and add more support beams underneath.

✔ Stacking multiple shelves? Leave at least 16 inches between each shelf for optimal storage flexibility.

📌 Pro Tip: Measure twice, cut once! Double-check your measurements before making any cuts to avoid wasting materials.

Now that you’ve planned your perfect garage shelf size, it’s time to start cutting the lumber! Move on to Step 2: Locating Wall Studs.

Related guides you might like:

➡️DIY Woodworking for Beginners: Ultimate Guide to Getting Started In 2025

➡️Master These 11+ Basic Carpentry Skills and Build Like a Pro

Step 2: Locate Wall Studs

No, you do NOT need to tear down your drywall… but you DO need to mount your shelves securely to the wall studs for maximum strength.

Attaching your shelf supports directly into wall studs instead of just drywall is critical for safety and durability. Even the best drywall anchors won’t cut it for heavy garage shelving—trust me, I’ve seen them fail!

Securing to wall studs matters because:

✔ Stronger & safer – Shelves mounted into studs can support heavy tools, bins, and equipment.

✔ Prevents sagging – Even well-anchored drywall can eventually weaken underweight.

✔ Lasts longer – A stud-mounted system is more stable and durable.

How to Find Wall Studs (The Right Way!)

1️⃣ Use a stud finder – The easiest and fastest way to locate studs behind drywall.

2️⃣ Try the “tap method” – Tap lightly along the wall and listen for a solid, less hollow sound (indicates a stud).

3️⃣ Use a strong magnet 🧲 – Run a magnet across the wall to locate drywall screws (they are fastened into studs usually). This method works best with stronger magnets and is a great trick if you don’t have a stud finder. There are also stud finding magnets for cheap.

4️⃣ Drill a tiny test hole – If unsure, drill a small pilot hole to confirm you hit a stud.

5️⃣ Mark each stud with a pencil – Once found, mark the center of each stud for accuracy.

6️⃣ Measure 16 inches apart – Most studs are spaced 16 inches on center, but some garages may have 24-inch spacing. Double-check before drilling!

📌 Pro Tip: If you miss a stud, insert a small piece of wire or a long drill bit into the test hole and wiggle it side to side. If it moves freely, you missed—slide left or right 1 inch at a time until you hit solid wood.

Now that you’ve found the studs, it’s time to move on to Step 3: Cutting the Shelf Supports.

Step 3: Cut 2×4 Support Pieces

Now that you’ve located your wall studs, it’s time to cut the support pieces for your shelves. These supports will hold the weight of your DIY garage shelves and provide stability for a long-lasting, sturdy build.

Using a pencil, speed square, and either a miter saw or circular saw, cut the following pieces:

| Wood Piece | Quantity | Length |

| Top Support (2×4) | 4 | 19 inches |

| Back Support (2×4) | 4 | 17½ inches |

| Diagonal Brace (2×4) | 4 | 22½ inches to the long point of the 45° angle cuts (***read image caption below) |

👉 Pro Tip: For a full 8-foot shelf, you’ll typically need 4 brackets. Cut all pieces at once for uniformity and efficiency.

Cutting Instructions

1️⃣ Measure & Mark: Use a tape measure and pencil to mark your cut lines accurately.

2️⃣ Use a Speed Square: Place a speed square against the 2×4 to ensure perfectly straight 90° and 45° cuts.

3️⃣ Set Up Your Saw:

- Miter Saw (Best Option) – Provides quick, accurate, and repeatable cuts.

- Circular Saw (Alternative) – If using a circular saw, you can use your speed square to help make straight crosscuts. Learn how to do this here.

4️⃣Cut All Pieces at Once: For efficiency and uniformity, cut all top supports, back supports, and braces in batches rather than one at a time. *This only really works with a miter saw

📌 Pro Tip: Label each piece with a pencil if needed (T for Top Support, B for Back Support, D for Diagonal Brace) to stay organized during assembly.

Now that you have all your support pieces cut, it’s time to start assembling the shelf brackets and securing them to the wall. Move on to Step 4: Assemble the Shelf Supports.

Step 4: Assemble the Shelf Supports

Now that you’ve cut all your support pieces, it’s time to assemble the shelf brackets. Each bracket consists of three 2×4 pieces forming a strong right-angle triangle, a solid shape for supporting heavy loads.

📐 Step-by-Step Assembly

1️⃣ Arrange the Pieces

- Lay the top piece (19 inches) and back piece (17½ inches) into an L-shape, forming a butt joint (as shown in the diagram). You can learn more about joinery in this complete woodworking guide for beginners.

- Ensure both pieces are flush and square.

📌 Pro Tip: Use a framing square to double-check that the joint is a perfect 90°.

2️⃣ Attach the Diagonal Brace (22½ inches, 45° cuts)

- Position the diagonal brace between the top and back supports to reinforce the bracket.

- Choose your mounting style (refer to diagrams when cutting):

- “Flat” style: The brace sits flat against both supports.

- “On-edge” style (stronger): The brace is turned on edge for extra rigidity.

📌 Pro Tip: If you’re a beginner, I recommend the on-edge style—it’s faster and easier to cut with a circular saw and increases strength. But give the other a go if you want the extra practice!

3️⃣ Secure with Screws

- Pre-drill holes to prevent wood from splitting.

- Use 3-inch wood screws to secure each joint firmly.

- Double-check for squareness.

📌 Pro Tip: Clamp pieces together while drilling to keep them from shifting during assembly.

Now that your brackets are assembled, it’s time to secure them to the wall studs and start installing your DIY garage shelves. Move on to Step 5: Mounting the Shelf Supports to the Wall.

Step 5: Mounting the Shelf Supports to the Wall

Now that you’ve built your shelf brackets, it’s time to secure them to the wall. Proper installation ensures maximum weight support and long-term stability.

Step-by-Step Installation

1️⃣ Align the First Support Bracket

- Hold the first bracket against the wall at your marked stud locations.

- Ensure the back support (17½-inch piece) is flush against the drywall.

2️⃣ Check for Level & Plumb

- Use a level (here’s a great beginner’s set) to make sure the bracket is both:

- Level with all the other brackets to prevents uneven shelving.

- Plumb (straight up and down) ensures proper weight distribution and looking like you know what your doing.

📌 Pro Tip: If working alone, use a temporary screw to hold the bracket in place while finishing securing it. Pre-drilling will make your life easier by yourself too.

3️⃣ Secure the Brackets to the Wall Studs

- Drill pilot holes through the brackets and into the wall stud to prevent splitting and to locate where it will sit.

- Drive in 3½-inch SDS screws or lag screws through the back support into the stud.

- Repeat for all brackets, spacing them every 16 inches (or according to your stud layout).

📌 Pro Tip: If your studs are spaced 24 inches apart, consider adding an extra bracket between them for added support or another sheet of ply for the shelf.

4️⃣ Double-Check & Adjust If Needed

- Once all brackets are installed, check for level one last time before moving on to the shelf installation.

⚠️ Safety Warning: Avoid Hitting Electrical & Plumbing

When screwing into studs, be cautious of hidden electrical wiring and plumbing inside the wall.

How to check for wires or pipes before drilling:

✔ Look for nearby outlets, plumbing, and light switches – Studs almost always run alongside them.

✔ Use a stud finder with live wire detection to check for electrical wiring.

✔ Drill pilot holes carefully – If resistance feels unusual or you hit metal, stop immediately.

With your shelf brackets securely mounted, it’s time to attach the actual shelving boards and complete your project!

Step 6: Cut and Install the Plywood Shelf for your DIY Garage Shelves

Now that your shelf brackets are mounted, it’s time to cut and install the plywood shelf surface. This is where all your tools, bins, and supplies will sit, so securing it properly is key to durability and long-term use.

Step-by-Step Installation

1️⃣ Cut the Plywood to Size

- Measure and mark a sheet of ¾-inch plywood to 8 feet long by 19 inches wide (or adjust based on your custom shelf size).

- Use a circular saw or table saw (my go-to) for a clean, precise cut.

📌 Pro Tip: When cutting plywood, use a fine-tooth blade to reduce splintering. Also use the “clamped down straight edge” trick for long plywood cuts to make sure they are perfectly straight.

2️⃣ Sand the Edges

- Use 120-150 grit sandpaper or a sanding block to smooth out rough edges.

- This helps prevent splinters and makes the shelf look more polished.

📌 Pro Tip: If you want a super smooth finish, slightly round over the front edge with a router or sanding sponge.

3️⃣ Position the Plywood on the Supports

- Place the cut plywood sheet on top of the installed shelf brackets.

- Ensure it’s centered and sits flush against the back wall.

📌 Pro Tip: If your shelf is longer than 8 feet, join two plywood sheets together over a middle support bracket for added strength.

4️⃣ Secure the Plywood to the Supports

- Pre-drill holes along each bracket to prevent splitting. (See diagram below)

- Use 1-5/8″ wood screws to attach the plywood to the top supports of the brackets.

📌 Pro Tip: If you plan to store extra heavy items, add more screws or use construction adhesive for extra holding power.

🎨 Optional: Paint or Stain for a Finished Look

Want a polished, professional finish? Consider painting or staining your DIY garage shelves:

✔ Paint – A coat of durable paint or polyurethane can help protect against spills, moisture, and scratches.

✔ Stain & Seal – Staining adds a richer, natural wood look while sealing helps prevent warping.

📌 Pro Tip: If storing chemicals, paints, or liquids, use an oil-based polyurethane or garage-grade paint for easy cleanup and durability.

With your plywood shelf installed, you’re almost done! In the final step, we’ll cover final adjustments, weight capacity tips, and how to load your new DIY garage shelves for maximum efficiency properly.

Step 7: Test for Strength & Organize Your Storage

Before loading up your brand-new DIY garage shelves, it’s important to test for strength and stability. This ensures your shelves are secure and can safely support the weight of your tools, bins, and supplies.

How to Test Your DIY Garage Shelves for Strength

✔️ Press down on the shelf – Apply firm pressure with your hands to check for movement, sagging, or shifting.

✔️ Reinforce weak spots – If you notice any wobbling, make sure your screws are sucked up tight. If there still is wobble then add extra 3-inch screws to the brackets or support beams.

✔️ Weight test – Place a 50 lb weight (such as a bag of concrete or a stack of heavy tools) on the shelf and observe for any bending or instability.

📌 Pro Tip: If you plan to store very heavy items (100+ lbs per shelf), consider:

- Adding extra brackets for more support.

- Using thicker plywood (1-1/8″ SturdiFloor inch instead of ¾ inch).

- Installing L-brackets underneath for additional reinforcement.

📦 Organize Your Storage Like a Pro

Now that your shelves are solid and secure, it’s time to maximize storage space by organizing everything efficiently.

✔ Store heavy items on the lower shelves(if you built multiple) – This keeps your storage stable and reduces strain on upper shelves.

✔ Use clear bins or label them– Group similar items together and label bins for easy access.

✔ Hang frequently used tools – Mount a pegboard or hooks above your shelves for extra storage.

✔ Create a dedicated workspace – Leave an open section for a workbench or tool station if needed. (Who’s ready for another DIY project?)

📌 Pro Tip: Plan for future storage growth. If you expect to add more tools or supplies later, leave extra shelf space for expansion.

You’ve successfully built strong, durable, and affordable DIY garage shelves that will keep your workspace organized for years to come. Now load them up and enjoy the extra space!

Next Steps: What’s Your Next DIY Project?

By following this simple 7-step process, you’ve built a set of sturdy, functional DIY garage shelves—without breaking the bank.

Now that your garage is more organized, what’s your next DIY project? Maybe a workbench, a tool storage rack, or another space-saving build?

✅ Before you go, check out these must-read guides to improve your woodworking skills and take on even bigger projects:

Upgrade Your DIY Game:

➡️ Best Woodworking Tools for Beginners – Essential tools for anyone serious about woodworking.

➡️ DIY Woodworking for Beginners – Learn foundational skills to tackle more DIY builds with confidence.

➡️ Essential Power Tools for Beginners – A breakdown of the must-have power tools for DIY projects.

🏗 More DIY Projects to Try:

➡️ First DIY Project Guide – A perfect step-by-step guide if you’re new to building.

📢 If this guide helped you, share it with a friend who needs better garage storage. And for more step-by-step DIY builds, sign up for my newsletter below!

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!