Basic Woodworking Terms for Beginners In 2025

Disclosure: This post may contain affiliate links from online retailers, including Amazon. If you click a link and buy tools or supplies, I may earn a small commission—at no extra cost to you. This allows me to provide you free helpful content, and I genuinely appreciate your support🤝 Learn more

Have you ever walked into a woodworking store or started watching a tutorial and suddenly felt completely lost by the jargon? I’ve been there! The first time someone told me to make a “dado cut,” I just nodded like I knew exactly what they meant, secretly panicking inside.

Woodworking terms like “rabbet,” “kerf,” and “chamfer” sounded more like fancy menu items than practical skills.

But here’s the good news: woodworking terms aren’t nearly as intimidating as they seem once you break them down into simple terms. Learning these basic woodworking terms won’t just make your projects easier, it’ll boost your confidence and help you tackle any woodworking challenge head-on.

I’ve gathered 25 of the most essential woodworking terms every beginner should know, and by the end of this guide, you’ll be speaking woodworking fluently in no time.

Ready to cut through the confusion and sharpen your woodworking vocabulary? Let’s dive in!

Why Knowing Basic Woodworking Terms Matters

I’ll admit something embarrassing…

I once wasted money buying the wrong type of lumber because I didn’t understand simple terminology.

Trust me, that’s a frustrating moment no beginner wants. Learning woodworking terms didn’t just save me from waste, it made communication with lumber suppliers and fellow woodworkers smooth as silk.

Projects and tutorials became way easier to follow when I finally understood the difference between rip cuts and crosscuts or a butt joint from a dado. Knowing proper woodworking language even boosted my confidence—sharing tips and experiences with fellow hobbyists became second nature.

Don’t overlook this point; lack of knowledge can turn simple tasks into complicated headaches.

Knowing your woodworking vocabulary can prevent unnecessary mistakes, frustration, and money down the drain. Plus, when you talk shop, you don’t want folks questioning your abilities just because you fumble over words.

Credibility in woodworking comes partly from sounding like you know what’s up. Making an effort to learn these terms early on pays off big time in every project.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Woodworking Terms for Parts of the Wood

When I started woodworking, one of the first hurdles was simply knowing the basic parts of wood and why they matter. So, let’s start here—these fundamental woodworking terms set the stage for everything else you’ll learn.

Grain

Wood grain refers to the direction, texture, and pattern formed by fibers in the wood. Grain direction matters because cutting with the grain usually gives smoother results, while going against the grain can cause splinters and rough cuts.

End Grain

End grain is what you see when wood is cut across its width, revealing the circular pattern of growth rings. Working with end grain can be tricky because it absorbs finishes differently and is prone to tear-out during cuts.

Face Grain

The face grain is the wider, visible surface of the wood board, usually used as the main surface for projects like tabletops or shelving. It’s generally smoother and easier to finish than end grain.

Edge Grain

Edge grain is the narrower side of a board, showing straighter, tighter grain patterns. It’s often used for glue-ups because it creates strong and stable joints.

Knot

Knots are circular imperfections caused by branches growing from the main trunk. While visually appealing for rustic projects, knots can weaken wood, making it harder to cut and prone to cracking or breaking if mishandled.

Sapwood

Sapwood is the lighter-colored, outer part of the wood closest to the bark. It contains active moisture and nutrients, making it softer and less stable compared to the darker heartwood.

Heartwood

Heartwood is the denser, darker-colored center of a tree. It’s usually harder, more durable, and less prone to warping, making it ideal for furniture and structural woodworking projects.

Essential Woodworking Terms: Measuring & Marking

Accurate measuring and marking can make or break your woodworking projects. Believe me, I’ve had my fair share of frustrations from tiny measuring mistakes. Here are the most essential woodworking terms to ensure precision every time:

Kerf

Kerf is the thickness or width of the cut a saw blade makes in wood. It’s crucial to account for kerf in your measurements to avoid undersized cuts or wasted material.

Scribe

To scribe means to mark a precise line directly onto wood for cutting or shaping. A sharp pencil or a specialized scribing tool ensures clarity and accuracy in marking.

Square

Square describes a perfect 90-degree angle between two surfaces or edges. Ensuring your project is square prevents uneven joints and wonky furniture—trust me, you’ll thank yourself later.

Related: How to Use a Speed Square: 7 Tricks for Perfect Cuts

Bevel

A bevel is an angled cut along the edge or face of the wood, typically less than 90 degrees. It’s often used for decorative edges or joints that fit snugly together.

Miter

A miter is a precise, angled cut—usually 45 degrees—used commonly in frames, moldings, and boxes to create clean corner joints.

Layout

Layout refers to marking and measuring your wood pieces accurately before cutting. A careful layout helps avoid wasted material and saves countless headaches down the road.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Woodworking Terms for Joints & Joinery

One of the best feelings in woodworking is when a joint fits just right. But believe me, that takes knowing your joinery terms and a bit of practice. Here’s a quick breakdown of essential woodworking terms for common joints:

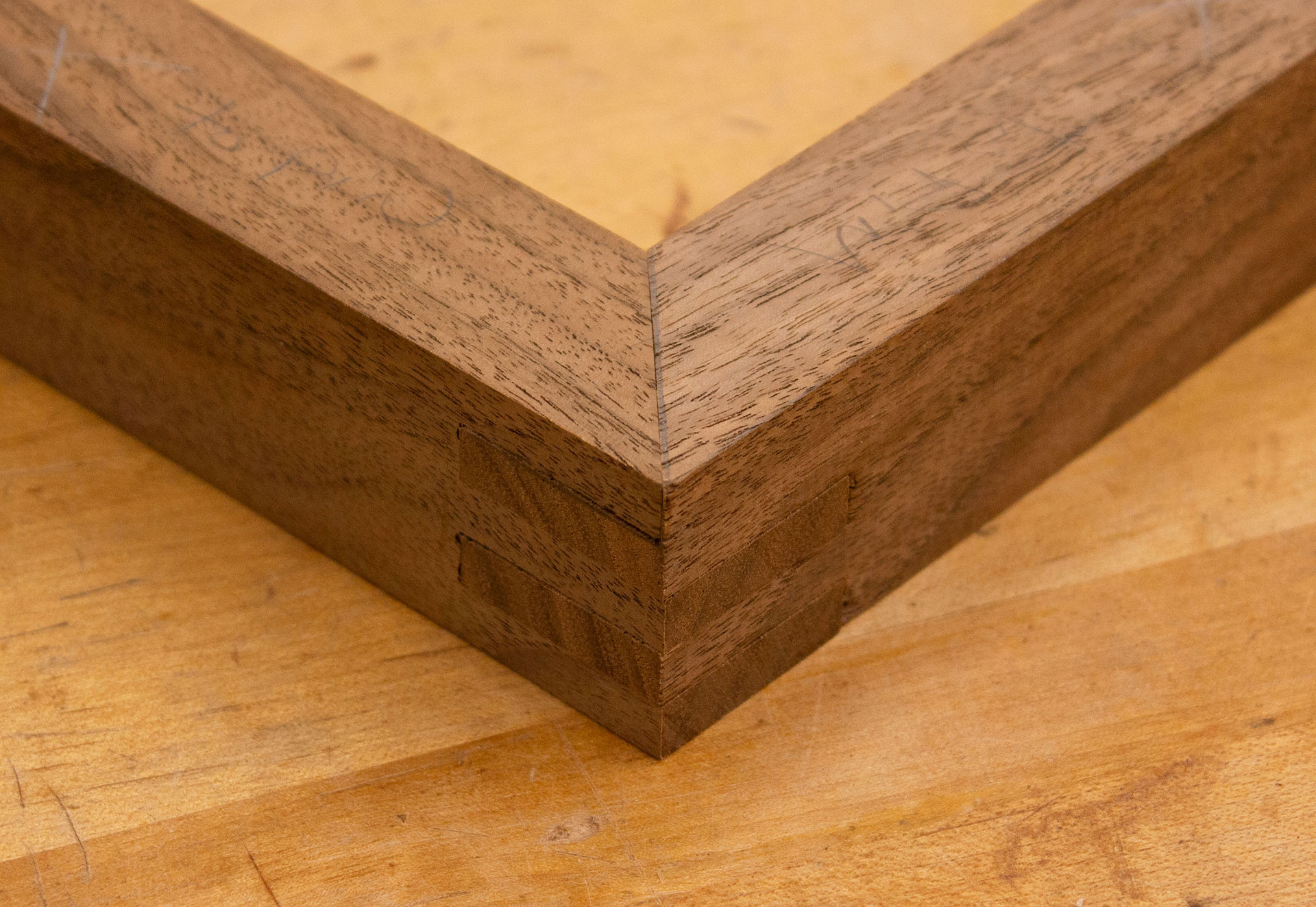

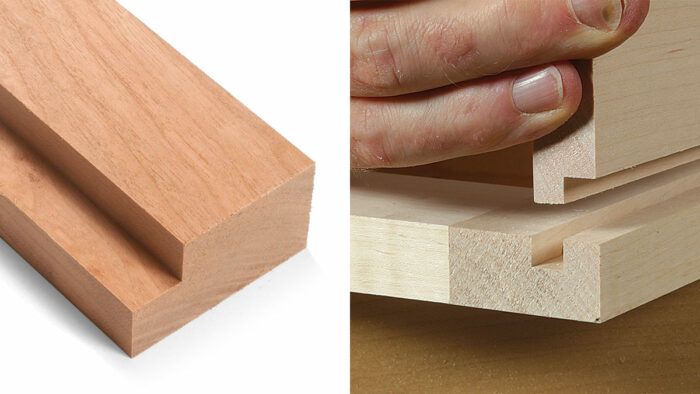

Dado

A dado is a flat-bottomed groove cut across the grain of a wood piece. You’ll use it a lot for shelving, cabinetry, and creating sturdy connections between pieces.

Rabbet

A rabbet is an L-shaped notch cut along the edge or end of a board. It’s typically used to join edges together neatly or to inset panels into frames.

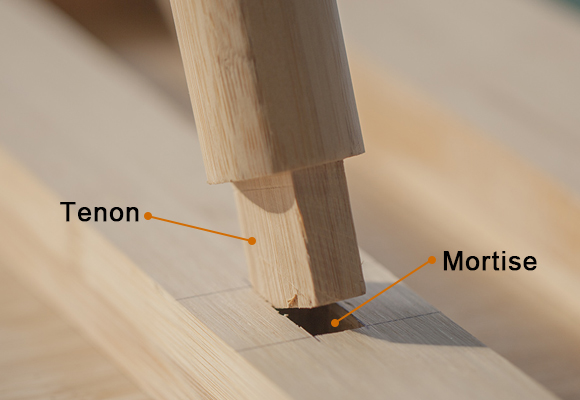

Mortise and Tenon

This classic woodworking joint consists of a “tenon” (a protruding piece of wood) fitting snugly into a matching “mortise” (a square or rectangular hole). It’s incredibly strong—perfect for furniture like tables or chairs.

Butt Joint

A butt joint is simply two wood pieces joined edge-to-edge or end-to-end, usually reinforced by nails, screws, or glue. It’s straightforward, but often weaker without additional reinforcement.

Dovetail Joint

A dovetail joint interlocks pieces of wood with wedge-shaped “tails” and “pins,” creating strong, durable connections that also look impressive—ideal for drawers and high-quality cabinetry.

Biscuit Joint

A biscuit joint involves inserting an oval-shaped piece of compressed wood (“biscuit”) into matching slots on two pieces of wood. It’s an easy way to align and strengthen joints, particularly for panel glue-ups.

Woodworking Terms: Types of Cuts & Shaping

Knowing the types of cuts and shaping techniques is essential for woodworking success. I learned the hard way that using the wrong cut or misunderstanding these terms can quickly ruin a project. Here’s a straightforward breakdown of the terms you need to master:

Rip Cut

A rip cut runs parallel with the grain of the wood. It’s typically used to narrow a board down in width and is usually performed on a table saw or with a circular saw.

Crosscut

A crosscut goes across the grain of the wood, typically shortening the length of a board. Crosscuts are common with miter saws and circular saws—just be sure your blade is sharp to avoid splinters.

Chamfer

A chamfer is a beveled edge (we already covered a bevel cut) that softens the sharp corner of wood, adding both style and reducing the risk of splintering. You’ll often see chamfered edges on tabletops and shelves.

Compound Cut

A compound cut combines a miter and bevel cut simultaneously. This advanced technique is mostly used in crown molding and detailed woodworking projects.

Resawing

Resawing involves cutting a thicker board into thinner pieces, essentially creating multiple boards from one. It’s perfect for book-matching panels or creating thin veneers.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Basic Woodworking Terms for Tools & Machinery

When starting out in woodworking, understanding your tools is a huge confidence booster. I’ve fumbled through enough tool manuals and workshops to know the simpler, the better. Here’s your straightforward guide to basic woodworking tool terms every beginner should know:

Jig

A jig is a custom-made accessory or guide designed to control the movement or positioning of your workpiece and tools. Trust me, a good jig can turn tricky tasks into easy ones every single time.

Fence

The fence is an adjustable guide attached to tools like table saws, band saws, and routers. It helps you make straight, precise cuts consistently—an absolute game-changer for accuracy.

Planer

A planer flattens and smooths wood surfaces and ensures consistent thickness across boards. One of my favorite machines for quickly transforming rough lumber into workable stock.

Joiner (Jointer)

:max_bytes(150000):strip_icc()/289-Benchtop-jointers1-dfcd0aabd3454bc98e625c09d9439c27.jpg)

A jointer creates a perfectly flat surface on wood edges, ensuring tight, seamless joints. Pair it with a planer, and your woodworking goes from beginner-level to professional-grade quickly. A joiner is a hand tool that created strong joints of various types.

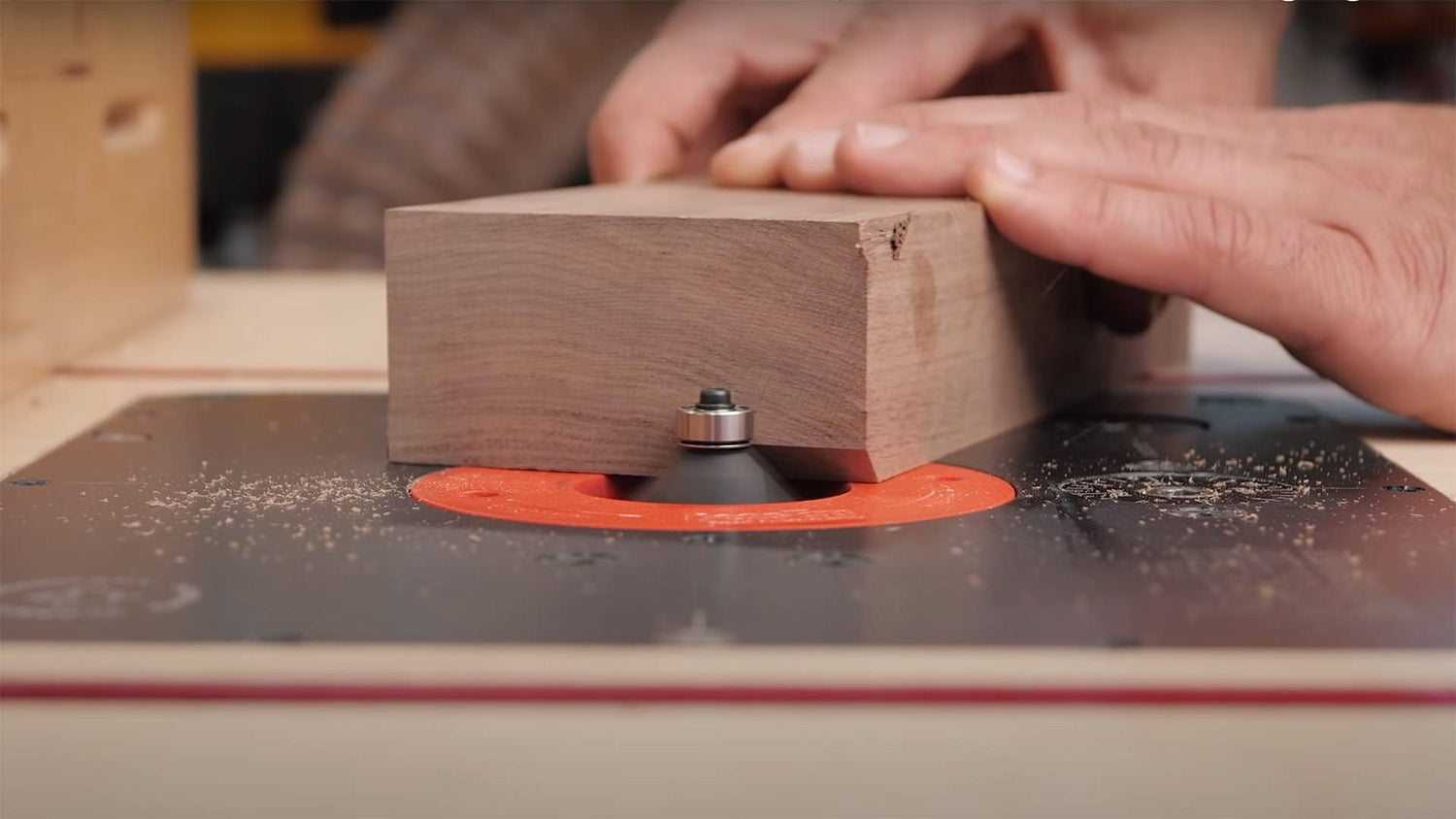

Router

A router is a versatile tool used to hollow out areas, shape edges, and create decorative patterns in wood. With the right bits, you can make your projects look incredibly professional.

Drill Press

A drill press provides precise, straight holes in your workpiece using a fixed drill head mounted above a stable platform. It’s essential for accuracy, especially when exact depth and angle matter.

Bandsaw

A bandsaw uses a continuous loop of blade stretched between two wheels for cutting curves, intricate shapes, and resawing thicker boards. It’s a real lifesaver when your projects get a little more creative.

Finishing Woodworking Terms You Need to Know

A good finish can transform your woodworking project from amateur to professional. I still remember the pride I felt when I nailed my first smooth finish after plenty of trial and error. Here’s a simple rundown of the most essential woodworking finishing terms you need to master as a beginner:

Sanding Grit

Sanding grit refers to the size of abrasive particles on sandpaper—the lower the grit number, the coarser the sandpaper. Start coarse (around 80-120 grit) and work your way up to finer grits (220-400 grit) for a smooth, flawless finish.

Finish

Finish is any protective coating applied to wood to enhance durability and appearance. Common options include polyurethane, varnish, shellac, and oils, each offering a unique look and level of protection.

Sealer

A sealer is applied before finishing to stabilize wood and reduce how much finish it absorbs. It ensures a smoother, more even final coat—especially critical with softer woods or end grain.

Varnish

Varnish is a durable, clear finish often used outdoors or on furniture that sees heavy use. It dries harder than other finishes, protecting your work from moisture and wear.

Stain

Stain adds color to your wood while highlighting its natural grain pattern. It’s perfect if you want to alter the wood’s appearance or match a specific decor style.

Topcoat

Topcoat refers to the final protective finish applied over stain or paint, providing extra durability and a professional look. Polyurethane is one of the most common and user-friendly options for beginners.

Woodworking Terms Final Thoughts

Mastering these basic woodworking terms for beginners truly changed the game for me. Suddenly, projects felt easier, tutorials made sense, and I could confidently talk shop with fellow woodworkers at the lumberyard. The best part? Now you’ve got these essential woodworking terms under your belt, too!

Ready to keep growing your woodworking skills? Don’t miss out—join my email list for exclusive tips, detailed guides, and helpful resources delivered right to your inbox. And make sure to check out my other popular posts like the Ultimate Guide to Woodworking and the must-read list of Essential Woodworking Tools for Beginners.

Let’s keep building and learning together—one woodworking project at a time!

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Woodworking Terms FAQs

What woodworking terms should beginners learn first?

Beginners should start by learning terms like grain, kerf, dado, rabbet, rip cut, crosscut, and chamfer. Mastering these foundational terms will make woodworking much easier to understand and enjoy.

Why is understanding woodworking terms important?

Knowing woodworking terms helps you clearly follow instructions, avoid costly mistakes, communicate better with other woodworkers, and significantly improve the quality of your projects.

What’s the difference between a dado and a rabbet?

A dado is a flat-bottomed groove cut across the grain of a board, typically for shelves. A rabbet, however, is an L-shaped cut along the edge or end of the board, often used for joints or fitting panels.

How do you know if your wood is square?

You can check if wood is square by using a carpenter’s square. Align it with the edges—if both sides align perfectly without gaps, your piece is square.

Which woodworking finish is best for beginners?

Polyurethane is typically the best finish for beginners because it’s easy to apply, dries clear, provides strong protection, and works well on most woodworking projects.