How to Choose the Right Jigsaw Blade: 7 Pro Tips

Disclosure: This post may contain affiliate links from online retailers, including Amazon. If you click a link and buy tools or supplies, I may earn a small commission—at no extra cost to you. This allows me to provide you free helpful content, and I genuinely appreciate your support🤝 Learn more

Ever burned through a jigsaw blade way too fast or butchered a cut you thought would be clean? Been there. Choosing the right blade is one of those things that seems simple… until you’re standing in the tool aisle staring at a wall of blades labeled with cryptic codes like TPI, HCS, or BIM.

Trust me—I’ve ruined more than a few projects because I didn’t use the right blade for the job. Whether you’re cutting hardwood, metal, PVC, or laminate, the blade you pick can make or break your cut—literally. In this guide, I’ll break down how to choose the right jigsaw blade in plain language, using real experience and no fluff.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

We’ll cover materials, tooth count, shank types, and more—and I’ll even walk through what blades I keep in my tool kit and why. By the end, you’ll know exactly what to grab next time you’re at the hardware store or loading up your cart online. Let’s get into it.

What Does a Jigsaw Blade Actually Do?

Alright, let’s start at the root of it: what’s a jigsaw blade actually doing under the hood?

When you squeeze the trigger, that blade isn’t spinning like a circular saw—it’s shooting up and down, fast as heck, in a straight vertical motion. It’s kind of the same motion as a reciprocating saw, or better known as a “sawzall”.

That up-and-down stroke is what lets you cut curves, plunge into material, and get way more control than you’d have with a bigger saw.

But here’s the thing: the blade is doing all the work. You’re just guiding the tool.

Early on, I treated jigsaw blades like they were all the same. Thought they were just skinny little saws you could swap in and out, no big deal. Wrong. I found out the hard way when I used a wood blade on thin aluminum sheet—it dulled in seconds and left a ragged mess.

The blade didn’t fail me. I failed it by not knowing what it was actually designed to do. And that’s really what how to choose the right jigsaw blade comes down to—knowing what each blade is built for.

A jigsaw blade is purpose-built. It’s not just for cutting — it’s for cutting a specific thing, in a specific way. The blade’s material, tooth pattern, length, and even the way it’s mounted (T-shank or U-shank) all determine how well it cuts, how long it lasts, and what kind of finish you get.

It’s kinda like drill bits—you wouldn’t use a wood bit on metal, right? Same logic applies here.

Whether you’re cutting plywood for a cabinet face or carving out a tight radius in laminate flooring, the blade has one job: make the cut clean, fast, and without burning out halfway through. But if you don’t know how to choose the right jigsaw blade for that job, it’s gonna show in the results.

And if it’s not the right one? You’ll feel it. The cut will fight you, the tool will vibrate more, and the results will suck.

So yeah, choosing the right jigsaw blade isn’t about overthinking—it’s about understanding the job you’re asking it to do. Once you nail down how to choose the right jigsaw blade, the rest gets way easier.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Understanding Blade Materials and Coatings

If you’ve ever wondered why some jigsaw blades snap after one sketchy cut while others keep going strong, it usually comes down to the blade’s material and coating. It’s not just about what it looks like—it’s about what it’s made to handle.

Let me tell you, when I was first starting out learning how to choose the right jigsaw blade, I didn’t give this stuff a second thought. I bought a bulk pack of random blades thinking, “Hey, they all fit my jigsaw, we’re good.”

Big mistake. I was cutting some MDF trim and the blade dulled halfway through the job.

Later found out it was a high-speed steel (HSS) blade meant for metal. Rookie move.

Here’s the breakdown of the four most common jigsaw blade materials:

:max_bytes(150000):strip_icc()/261i25-aa517231ac5c48a6a91e0b81b79ab06e.jpg)

- High Carbon Steel (HCS): These are soft, flexible, and perfect for cutting softer materials like wood and plastic. They don’t last super long, but they’re cheap and get the job done. I keep a stash of these for quick cuts where precision isn’t critical.

- High Speed Steel (HSS): These are tougher and designed to resist heat, which makes them ideal for metal and hard plastics. They don’t flex as much, so they’re more brittle, but they hold up better under pressure—literally.

- Bi-Metal (BIM): These are like the best of both worlds—flexible spine with hardened teeth. They’re my go-to when I don’t want to think too hard about blade choice. They last longer and can cut a wider range of materials.

- Carbide Grit or Carbide-Tipped: These are the tanks of the jigsaw world. Great for ceramic, tile, cement board, and even some metals. Expensive, but worth it when you need ‘em.

And then you need to know how to choose the right jigsaw blade coatings too—something most DIYers totally overlook. Coated blades can reduce friction and keep the blade cooler, which means longer life and cleaner cuts.

I’ve used Teflon-coated blades when cutting sticky materials like laminate or particle board, and man, what a difference. Way less gumming up, way fewer burn marks.

So if you’ve ever wondered why one blade melts through PVC while another gets stuck and smokes like a campfire, now you know—it’s the material and the coating doing (or not doing) their job.

Bottom line on how to choose the right jigsaw blade: match the blade’s material to the material you’re cutting. Otherwise, you’re just wasting blades and burning through your patience.

How TPI Affects Your Cuts (Teeth Per Inch)

TPI, which stands for teeth per inch, might sound like one of those boring specs only tool nerds care about, but let me tell you, it makes or breaks your cut. Literally.

The first time I cut a piece of thin plywood with a low-TPI blade when I was learning how to choose the right jigsaw blade, I didn’t realize I was about to splinter the heck out of it. The blade tore through the wood like a mini chainsaw, fast but ugly.

On the flip side, I once tried using a fine 20 TPI metal blade on a 2×4… felt like I was dragging the saw through syrup. It chattered, burned the wood, and took forever.

- Low TPI (6–10) = faster, rougher cuts. Perfect for thick, soft materials like construction lumber.

- Mid TPI (10–14) = a nice balance for smoother wood cuts or general-purpose use.

- High TPI (15–24+) = slower, smoother cuts, better for metal, plastic, or detailed work in hardwood.

A good rule? The thinner and harder the material, the higher the TPI you want. You want more teeth biting gradually into dense stuff like metal or PVC.

But if you’re ripping through a 2×6 or cutting up old pallets? Go low—let the blade eat.

There’s also these hybrid blades called “progressor” blades where the TPI increases from the base to the tip. I’ve used those when I’m not exactly sure what I’m cutting into (demo jobs or weird layered materials). They’re like the Swiss Army knife of jigsaw blades—not always perfect, but super handy.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

Oh—and one thing most people don’t think about when learning how to choose the right jigsaw blade is blade control. High-TPI blades tend to vibrate less and give you more control, which helps a ton on curves or detailed work.

At the end of the day, just remember:

- Low TPI = aggressive, fast, rough

- High TPI = slow, smooth, clean

Choose based on your project—not just what’s in your toolbox.

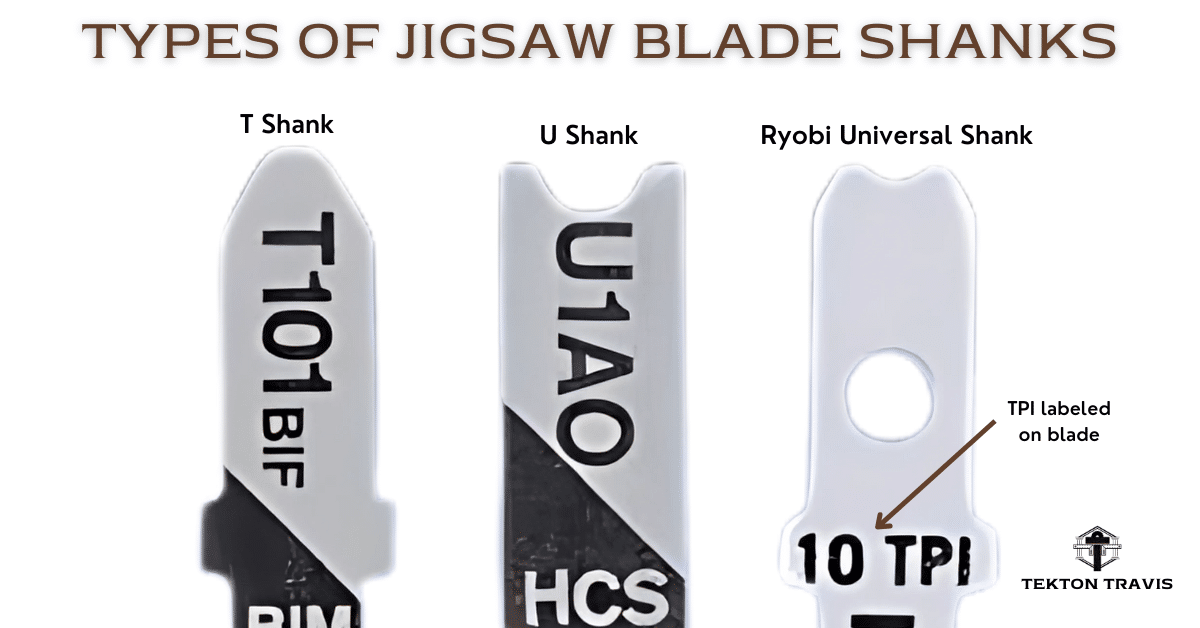

U-Shank vs T-Shank: What’s the Difference?

So you grab a new pack of blades, head back to your garage, go to pop one in—and it won’t lock into place…

Yeah, I’ve been there… I still have a pack of U-shank blades that I bought accidentally a long time ago.

It’s one of those forehead-slap moments. What I didn’t know back then was that jigsaw blades come with different shank types, and if you don’t match the blade to your saw, you’re outta luck.

There are two main kinds you need to know to choose the right jigsaw blade:

- T-Shank Blades: These are the most common nowadays and fit almost all modern jigsaws. The “T” at the top locks into the tool-free blade clamp system. Easy in, easy out. I use T-shanks 99.9% of the time, especially since I got tired of messing with screw-in blade holders.

- U-Shank Blades: These are older-style blades with a rounded top and sometimes require a screwdriver or Allen key to install. They’re still around, but mostly on older or budget tools. Unless you’ve got a vintage jigsaw or one of those “starter kit” saws, you’re probably not using U-shanks anymore.

A good rule of thumb for knowing how to choose the right jigsaw blade?

If your jigsaw has a tool-free blade change system, it’s almost definitely made for T-shank blades.

Still, always check your manual or blade clamp before buying a bulk pack.

I made the mistake once of ordering a box of U-shank blades online without double-checking—got a killer deal too—and when they showed up, none of them fit.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

They wound up just floating around in my truck to this day… Lesson learned.

Now I just stick to T-shanks across the board. Easier, more secure, and way faster when you’re switching blades in the middle of a job.

Related:

Matching the Blade to the Material

This is where a lot of DIYers and beginner woodworkers go wrong when learning how to choose the right jigsaw blade—including me back in the day. You grab a blade and just start cutting, thinking “Eh, it’ll probably work.”

Spoiler alert: it doesn’t… If you care about how your project will turn out at least.

Matching the blade to the material is everything if you want clean cuts, longer blade life, and less frustration.

Let’s break it down by material:

- Wood: For softwoods and general woodwork, I usually go with a 6–10 TPI high carbon steel blade. If I want a cleaner cut in plywood or finish work, I bump up to 12+ TPI and sometimes use a reverse-tooth blade to reduce splintering on the top side. If I’m doing tight scroll cuts for a pattern? I reach for a scrolling blade with a narrow width and tighter teeth.

- Metal: First mistake I ever made here? Using a wood blade on a thin sheet of steel. I dulled it in seconds and got nowhere. For metal, I stick with bi-metal or HSS blades in the 18–24 TPI range. Don’t try to force the cut—let the blade do the work, and use some cutting oil if you’ve got it.

- PVC & Plastics: Go mid-range TPI, around 10–14, and make sure you’re not going too fast or you’ll melt the plastic. I’ve literally watched PVC bubble from heat buildup when I rushed a cut.

- Laminate & Veneer: These are tricky because they love to chip. I always go with a reverse-tooth blade or a fine-tooth laminate blade designed to cut on the downstroke. Way cleaner results and no need to tape the surface (although sometimes I still do for peace of mind).

- Ceramic & Tile: You need a carbide-grit blade, period. Don’t try to use anything else unless you enjoy snapping blades and cracking tiles. These blades don’t have teeth—they grind through the material.

When you know how to choose the right jigsaw blade, the tool feels smoother, the cut stays on line, and your jigsaw doesn’t sound like it’s choking. And you don’t waste time trying to sand down ugly cuts afterward.

Real talk: one of the best things I ever did was build a little “go-to” blade kit sorted by material. I labeled everything and made it dummy-proof—because when you’re mid-project, you don’t want to be Googling “best blade for PVC” with glue drying on your hands.

Specialty Blades: When and Why to Use Them

There’s a blade out there for just about every weird cutting situation you can imagine. But the trick is knowing when a specialty blade will actually help… and when it’s just overkill.

Here are a few I’ve tested (sometimes successfully, sometimes not so much):

- Reverse-Tooth Blades: These cut on the downstroke instead of the upstroke, which means the splinters stay under the material, not on top. These are my go-to for laminate, melamine, or pre-finished plywood. If you’ve ever installed IKEA cabinets or cut laminate countertops, this blade will save your sanity—and your edge finish.

- Scrolling Blades: These blades are super narrow and made for tight, intricate curves. I use these when I’m tracing out complex patterns or doing decorative work. The learning curve is real—if you rush the cut, you’ll bend the blade or veer off path—but once you get a feel for it, they’re awesome.

- Progressor Blades: This is one of my favorites for demo work or mixed materials. They start coarse at the base and get finer toward the tip. I’ve used them when I didn’t know exactly what I’d hit inside a wall—wood, nails, drywall, PVC… they chew through it all without blowing apart mid-cut.

- Carbide Grit Blades: No teeth, just grit. Perfect for ceramic tile, cement board, and even fiber cement siding. I used one of these cutting HardieBacker for a bathroom job and it held up way better than I expected. Not fast, but it gets the job done clean.

- Down-Cut Laminate Blades: Kind of a specialty within a specialty. They cut clean edges into laminate tops and veneers by pulling fibers downward. Great for clean, chip-free finishes—especially if you don’t want to tape off the cut line.

Review the following image of a Diablo Jigsaw blade set I like that includes a couple more special blades.

Now, here’s the flip side: don’t fall into the trap of thinking you need a specialty blade for everything. I’ve bought scrolling blades for straight cuts (didn’t end well), or tried to force a progressor blade on fine finish work. Total mismatch.

In most cases, you’re better off learning how to use 3–4 reliable blade types really well, and then grabbing specialty blades when the job truly calls for it. They’re tools—not magic.

My Favorite Jigsaw Blades (From Experience)

You know how some tools or accessories just earn their spot in your kit? These blades have done that for me. I’ve gone through dozens of brands and blade sets over the years—some were solid, some were junk, and a few blew me away.

Here’s what I like and why:

- Bosch 30-Piece Jigsaw Blade Kit: This is probably my most-used jigsaw blade kit. It covers wood, metal, and plastic, and all the blades are T-shank, so they work with most modern saws. The T101B blades in that set are my go-to for clean wood cuts. I’ve ripped through cabinet-grade plywood with these and gotten glass-smooth results.

- Diablo (by Freud) Blades: These things are tanks. They last forever compared to cheapo blades. I use their blades very often for cutting pipe, brackets, and other metal odds and ends. This kit is a great value.

- DEWALT Blade Set: Their narrow scroll blades are surprisingly durable for detail work. I’ve used them on custom signs, trim details, and curved cabinet cutouts. Takes some control, but they’re sharp and reliable.

- Lenox Carbide Grit Jigsaw Blade: This one saved my butt during a bathroom remodel when I had to cut through HardieBacker. Smooth grinding action and zero teeth chatter. I don’t use it often, but I never start a tile job without it in my bag.

- Makita Wood Jigsaw Blades: If I’m shopping local and can’t get Bosch, these are my fallback. Solid quality and a bit stiffer, which helps on straighter cuts.

- Festool Jigsaw Blades: I don’t use these often, but they are some high-performance blades to be expected from a high-end woodworking tool company. Can’t go wrong here but you’ll be paying for premium quality.

And for the record—those $9 variety packs of 50-100 from no-name brands on places like Amazon?

Most of them are garbage for any real work.

I’ve snapped more than I care to admit and ended up wasting time and money trying to save a few bucks. Now I just spend a little more upfront and keep backups of my favorites in a labeled organizer so I’m never scrambling mid-project.

I recommend doing the same.

If I were to only pick 1-2, I’d go with these Bosch and Diablo sets.

Recommended Bosch Kit

My personal go-to kit I love using.

Recommended Diablo Kit

A kit with great value and performance.

Bottom line: the blade brand matters way more than people think. Once you find the ones that work for you, just stock up and keep ’em handy.

Common Mistakes When Choosing Jigsaw Blades

I used to think any jigsaw blade would get the job done if I just went slow and steady. Wrong. Over the years, I’ve learned—mostly the hard way—that knowing how to choose the right jigsaw blade can save time, improve quality, and protect your sanity.

The wrong one? That’s just asking for trouble.

Here are some of the biggest mistakes I’ve made (and seen others make) when choosing jigsaw blades:

- Choosing Based on Price Alone: I once bought a knock-off 52-blade pack from Amazon. Looked like a steal. I think I got two decent cuts out of the entire set before they started snapping mid-job or dulling in minutes. Lesson learned: cheap blades cost more in the long run.

- Using a Wood Blade on Metal: This one’s just painful. I was in a hurry, grabbed the first blade I saw, and tried cutting through an aluminum threshold. Smoked the blade, overheated the motor, and completely tore up the metal. Always match the blade to the material.

- Ignoring TPI or Blade Specs: Early on, I didn’t even know what TPI meant. I’d just grab whatever blade “looked right.” The result? Splintered plywood, melted plastic, and a whole lot of wasted time. Once I learned to read the labels and match blade specs to the task, my cuts got way cleaner.

- Overusing a Single Blade Type: I used to think one “good” all-purpose blade could handle everything. Nope. I burned through my favorite scrolling blade trying to cut metal brackets once—because I was too lazy to switch. It pays to pause and change blades when needed.

- Not Cleaning or Storing Blades Properly: Tossing blades in the bottom of a toolbox leads to dull teeth, bent shanks, and rust. I keep mine in a labeled plastic case now. Makes a difference, especially when you’re working fast and don’t want to second-guess your gear.

Honestly, most of these mistakes come from rushing or not really understanding how to choose the right jigsaw blade. Once I started treating blades like task-specific tools—rather than just accessories—I got way better results.

So if you take nothing else away from this post, remember this: don’t just use “a” jigsaw blade. Use the right one after learning how to choose the right jigsaw blade from this post.

How To Choose The Right Jigsaw Blade Final Thoughts

Look, I’ve wasted more blades—and ruined more cuts—than I’d like to admit. But once I finally learned how to choose the right jigsaw blade, everything changed. My cuts got cleaner, my blades lasted longer, and I actually started enjoying the process instead of fighting with my tools every step of the way.

Hopefully, this guide helps you know how to choose the right jigsaw blade and saves you some of the same frustration. Whether you’re just getting started or looking to level up your DIY game, the blade you use matters way more than most people think. And once you get the hang of choosing the right one, your projects will start turning out like you imagined—or better.

If this helped, there’s a ton more where that came from. Check out my guide on How to Use a Jigsaw: 9 Easy Steps for Perfect Cuts and Ultimate Guide to Woodworking Tools for Beginners.

You can also explore some of the other real-world DIY tips I’ve got up on the site.

And hey—if you want weekly DIY know-how, tool breakdowns, and project ideas straight from someone who’s been in the sawdust for years? Join my email list. I’ll send the good stuff, no fluff, PLUS 3 FREE workbench building plans!

Let’s keep building better, together.

Build Smarter – For FREE!

Join the Tekton Crew and grab 3 FREE Workbench Build Plans with 3D models—plus exclusive DIY tips, tool reviews, and more!

How to Choose the Right Jigsaw Blade FAQs

What is the best jigsaw blade for cutting wood?

For most wood projects, a high carbon steel (HCS) blade with 6–10 TPI works great for fast, rough cuts. For cleaner results in plywood or finish work, use a 12–20 TPI blade or even a reverse-tooth blade to reduce splintering.

Can I use one jigsaw blade for all materials?

Technically, some blades claim to be “multi-purpose,” but in reality, it’s better to match your blade to the material. Wood, metal, plastic, laminate, and tile all require different blade types to cut efficiently and cleanly.

What does TPI mean on a jigsaw blade?

TPI stands for teeth per inch. A lower TPI (like 6–10) gives you fast, rough cuts in soft materials. Higher TPI (15–24+) is better for smoother cuts and harder materials like metal or PVC.

What’s the difference between T-shank and U-shank blades?

T-shank blades are designed for tool-free blade changes and fit most modern jigsaws. U-shank blades are older and may require tools to install. Always check your jigsaw’s blade clamp to know which one it takes.

Why is my jigsaw blade burning the wood?

This usually happens when the blade is dull, has too high a TPI for the material, or if you’re pushing the tool too fast. Try a fresh blade with fewer teeth and let the saw do the work.

How long do jigsaw blades last?

It depends on the material you’re cutting and the blade type, but most blades are good for many solid cuts. Bi-metal and carbide blades last longer, especially in tougher materials like metal or tile.

Can I cut curves with any jigsaw blade?

You can, but for tight or intricate curves, a scrolling blade is your best bet. It’s narrower and more flexible, which helps you follow tighter cut lines without forcing the tool.